Team:ETH Zurich/lab/chip

From 2014.igem.org

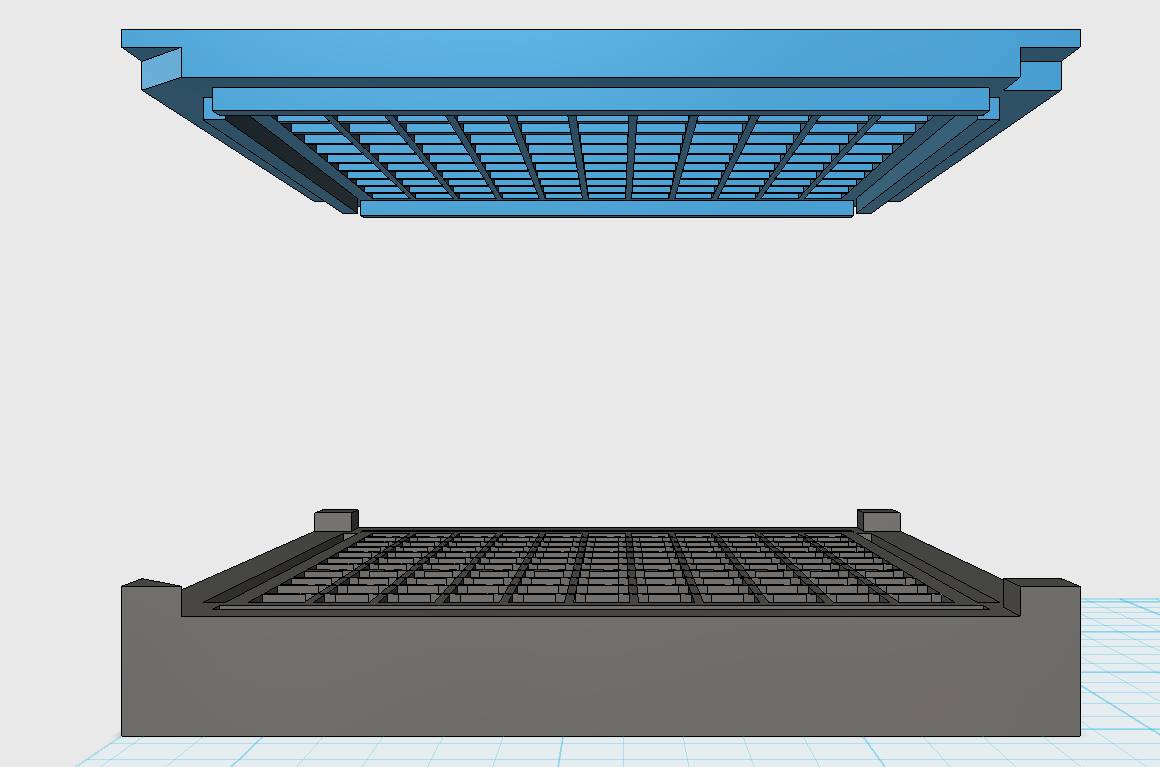

Millifluidic chip

Overview

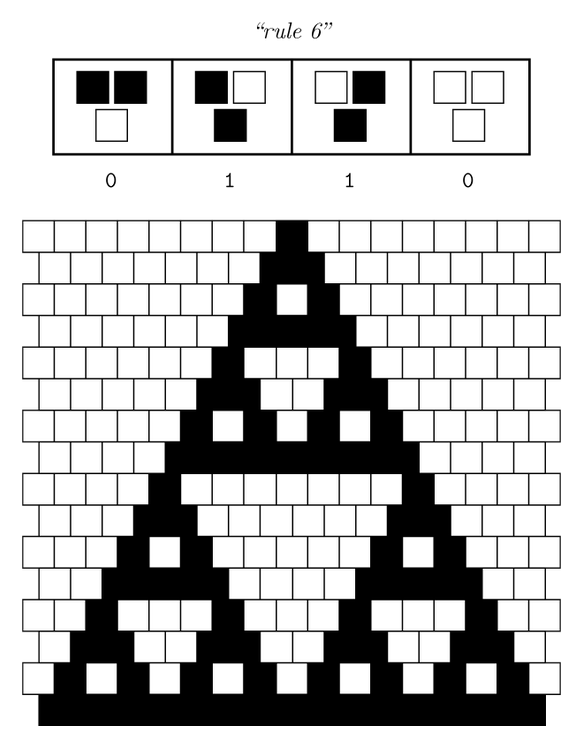

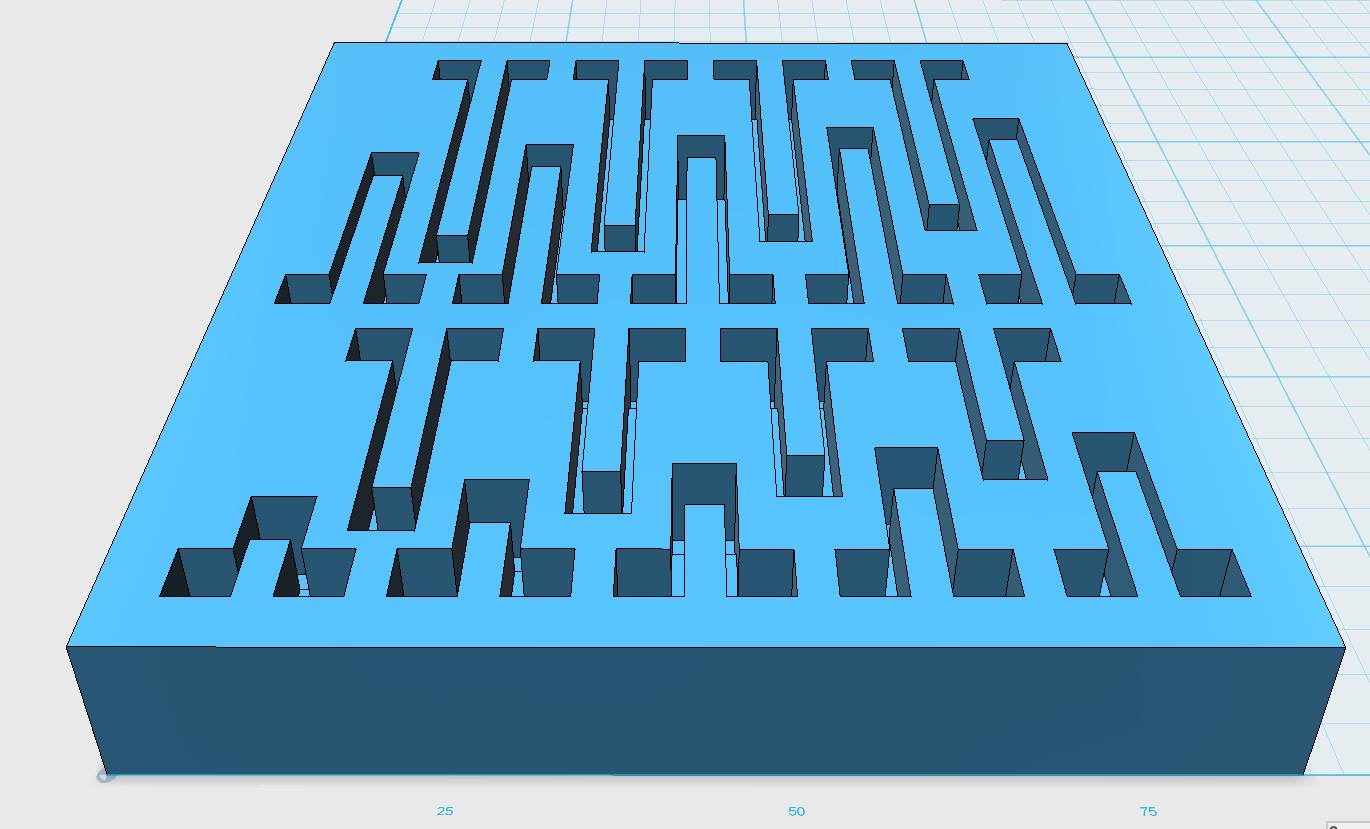

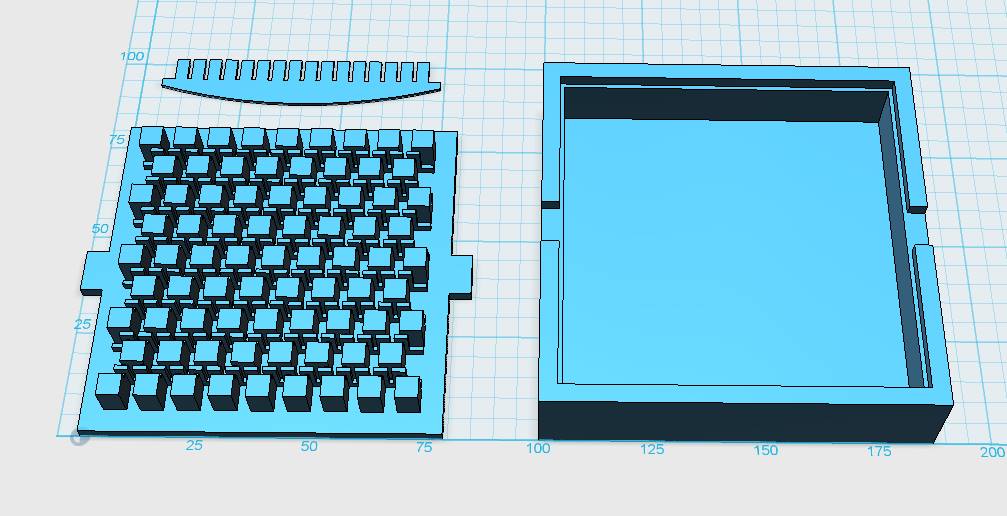

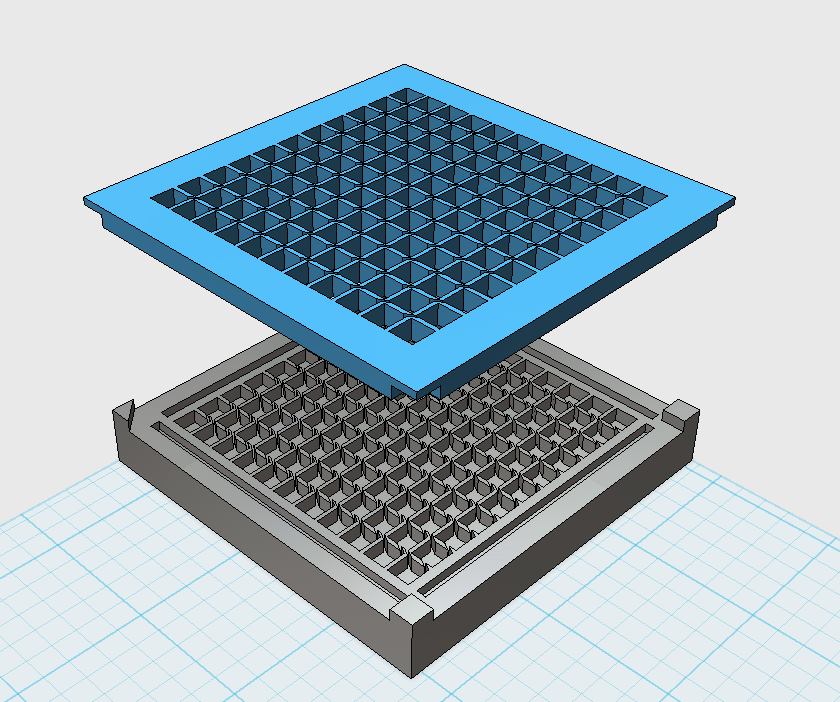

Our project aims for the biological implementation of cellular automata, so we had to find a way to create a regular grid of cells with a defined neighborhood as shown in the picture below. Therefore, we investigated the combination of additive manufacturing (3D-printing) and PDMS chip fabrication for applications in synthetic biology. This rapid prototyping approach allowed us to update our chips continuously according to new insights from modeling or the wet lab and to avoid more intricate photolitographic approaches, which generally require clean room access, relatively expensive raw materials, and in depth knowledge of etching techniques. As a result, we are convinced that the tinkering with 3D-printing for mold creation is more economical and perfectly in line with the do-it-yourself spirit of iGEM.

Mold Design

Our custom-made plates and molds were design using a common personal computer and a 3D computer aided design (CAD) software package that is freely available ([http://www.123dapp.com/design Autodesk123D Design]). The CAD models were exported as mesh files (.stl) to the 3D printer's software ([http://www.makerbot.com/support/makerware/troubleshooting/ MakerWare]). The dimensions of the device-structures were usually between 1 mm and 5 mm, falling in the range of millifluidics.

3D-Printing and Rapid Prototyping

PDMS Chip Preparation

Time-Lapse Movies

"

"