Team:ETH Zurich/lab/bead

From 2014.igem.org

(→Loading the Chip) |

(→Production) |

||

| Line 28: | Line 28: | ||

===Production=== | ===Production=== | ||

{| | {| | ||

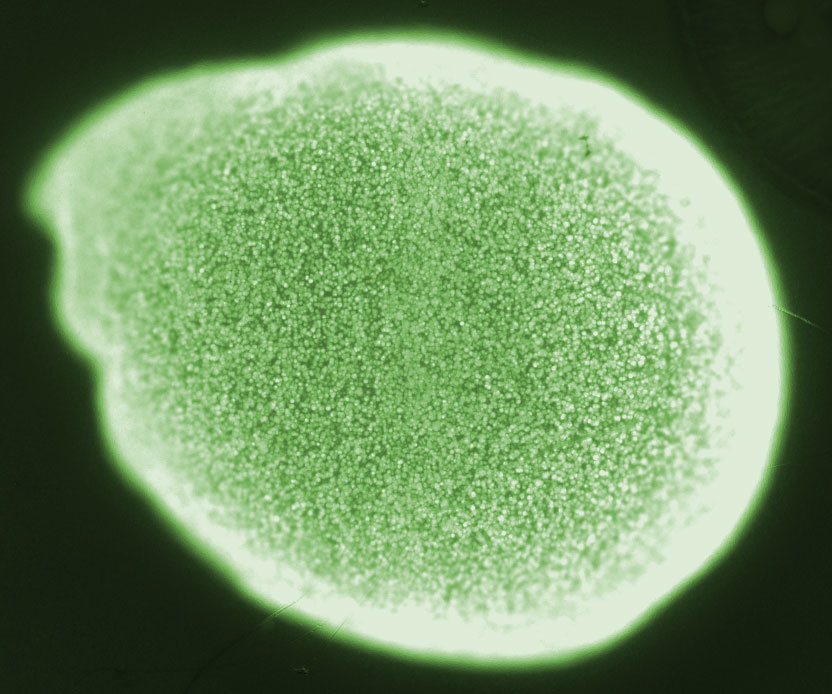

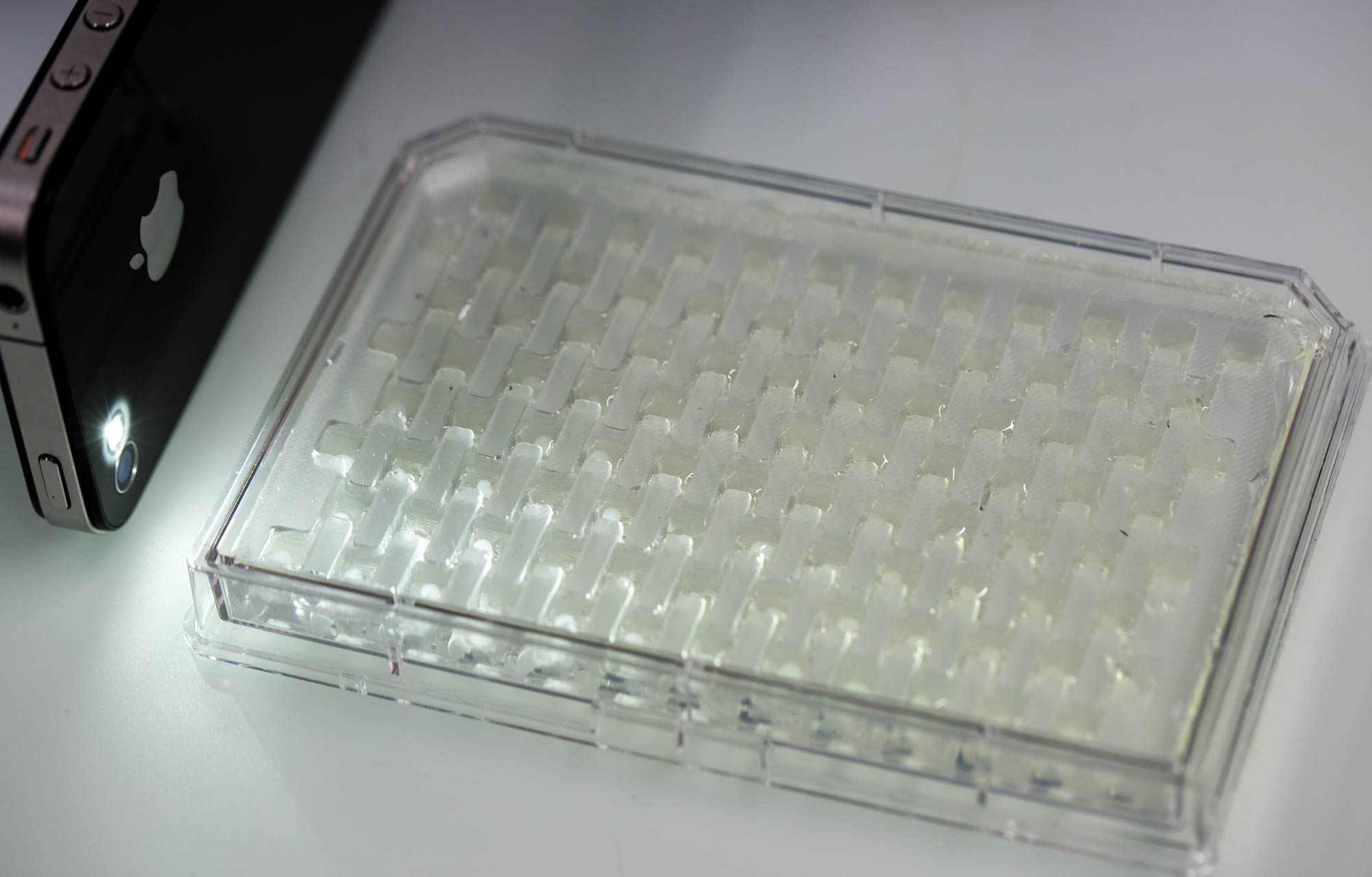

| - | [[File:ETH2014_BeadsProduction.jpg|left|250px|thumb| '''Figure 3 | + | [[File:ETH2014_BeadsProduction.jpg|left|250px|thumb| '''Figure 3 Bead production.''' Alginate droplets are gelling in the CaCl<sub>2</sub> solution in the beaker placed under the needle device]] |

Bacteria are resuspended and diluted in NaCl-solution (0.9 % in H<sub>2</sub>O) so as to achieve the desired cell density. Here, we aimed at a comparably high concentration of 10<sup>7</sup> bacteria per bead (3 mm diameter). The resuspension was added to alginate (2.5%) to reach a alginate concentration of 2%. The viscous solution is filled into a syringe containing an appropriate needle device and extruded at a constant, slow velocity. Ideally, the droplets should fall form a height of approximately 30 cm into a 100 mM CaCl<sub>2</sub> solution. In the CaCl<sub>2</sub> solution gelling of the alginate droplets will occur instantaneously. To avoid excessive salt stress for the bacteria the beads should be transferred to a 10 mM CaCl<sub>2</sub> solution. | Bacteria are resuspended and diluted in NaCl-solution (0.9 % in H<sub>2</sub>O) so as to achieve the desired cell density. Here, we aimed at a comparably high concentration of 10<sup>7</sup> bacteria per bead (3 mm diameter). The resuspension was added to alginate (2.5%) to reach a alginate concentration of 2%. The viscous solution is filled into a syringe containing an appropriate needle device and extruded at a constant, slow velocity. Ideally, the droplets should fall form a height of approximately 30 cm into a 100 mM CaCl<sub>2</sub> solution. In the CaCl<sub>2</sub> solution gelling of the alginate droplets will occur instantaneously. To avoid excessive salt stress for the bacteria the beads should be transferred to a 10 mM CaCl<sub>2</sub> solution. | ||

<br> | <br> | ||

Revision as of 23:27, 17 October 2014

Beads

Overview

Properties

Production

Loading the Chip

"

"