Team:ETH Zurich/project/applications

From 2014.igem.org

(→3D-Printing in Biology) |

(→Alginate-Microencapsulated Implants) |

||

| Line 9: | Line 9: | ||

| - | [[File:ETH_Zurich_2014_Application_implant.png|center|frame|500px|Modular therapeutic alginate-microencapsulated implants which communicate on orthogonal channels. Each module can be exchanged or separately updated depending on the disease.]] | + | [[File:ETH_Zurich_2014_Application_implant.png|center|frame|500px|thumb|'''Figure 1''' Modular therapeutic alginate-microencapsulated implants which communicate on orthogonal channels. Each module can be exchanged or separately updated depending on the disease.]] |

| - | + | ||

| - | + | ||

==3D-Printing in Biology== | ==3D-Printing in Biology== | ||

Revision as of 23:16, 17 October 2014

Applications

Biocomputation

Future development of synthetic biological systems will require the implementation of reliable synthetic circuits. These genetic circuits will be designed to program new biological behaviour, dynamics, and logic control[1]. A well established multichannel orthogonal communication system is crucial for efficient biological computation which is subsequently required for the performance of the cells tasks. In order to achieve the goals of our project we need to thoroughly characterise available components, improve their performance, and develop novel constructs for robust multichannel orthogonal communication and subsequent logic processing. With our findings we will try to make a contribution to the field of biological computation by enabling further development of complex systems that depend on the interaction between its subcomponents.

Alginate-Microencapsulated Implants

These biological computers in turn need to find a way to be implemented in patients, if they are developed for therapeutic use. A promising application of such synthetic biological systems is cell based therapy by alginate-microencapsulated implants[2][3]. In our project we try to generate complex patterns using a grid of alginate beads by exploiting their communication and input integration systems. These beads are incapable of functioning in isolation but generate complex patterns when used together on the grid. We believe that this can be a significant step for the development of artificial organs composed of multiple alginate-microencapsulated implants. Analogous to our system, these encapsulated implants work together to perform the overall task which otherwise, could not have been achieved by a single implant working in isolation. Each encapsulated component can be seen as module that can be exchanged or updated depending on the properties of the disease to be treated.

3D-Printing in Biology

|

|

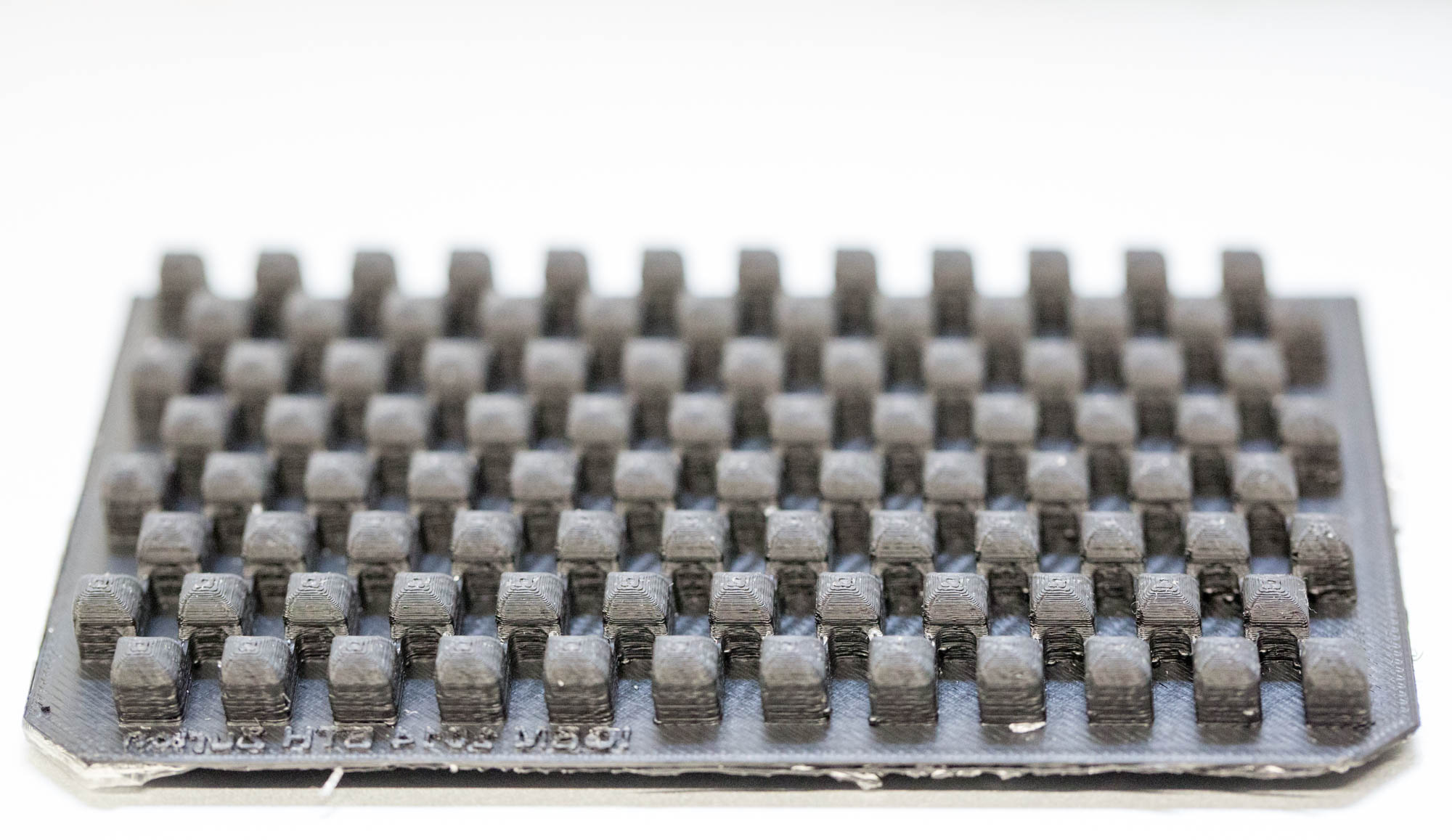

| ABS based mold as template for a PDMS millifluidic chip | PDMS millifluidic chip from ABS mold compatible with common microtiter plate readers |

"You envision something, draw it with the right software, and then print it in three dimensions—regardless of how many parts it has, how they interlock, or whether they will even be accessible once your creation is completed. With this strategy, anyone can make almost anything"[36]. In more production oriented, classical engineering disciplines this vision of additive manufacturing and rapid prototyping is already established as an useful standard application. However, the technology is also valuable for production of custom made laboratory equipment[31], in particular in more technology oriented sub-disciplines such as synthetic biology. We have shown the feasibility of 3D-printing for microtiter plates and mold production and make the files available for other applications via the [http://3dprint.nih.gov/ NIH 3D Print Exchange].

"

"