Team:Aachen/Project/2D Biosensor

From 2014.igem.org

(→Optimal chip configuration) |

(→Optimal chip configuration) |

||

| Line 146: | Line 146: | ||

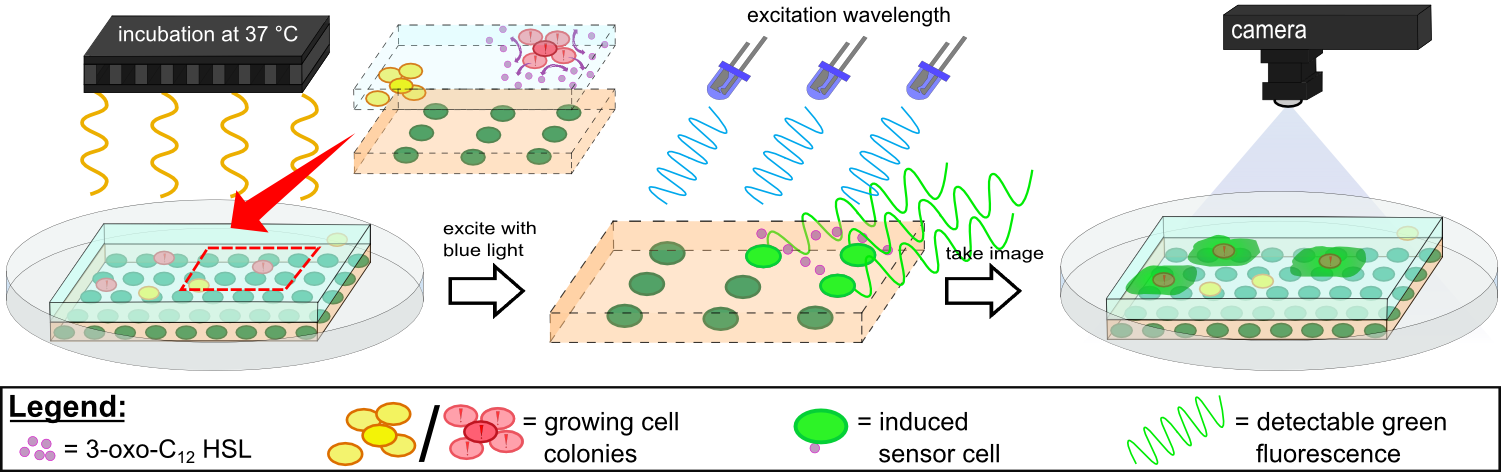

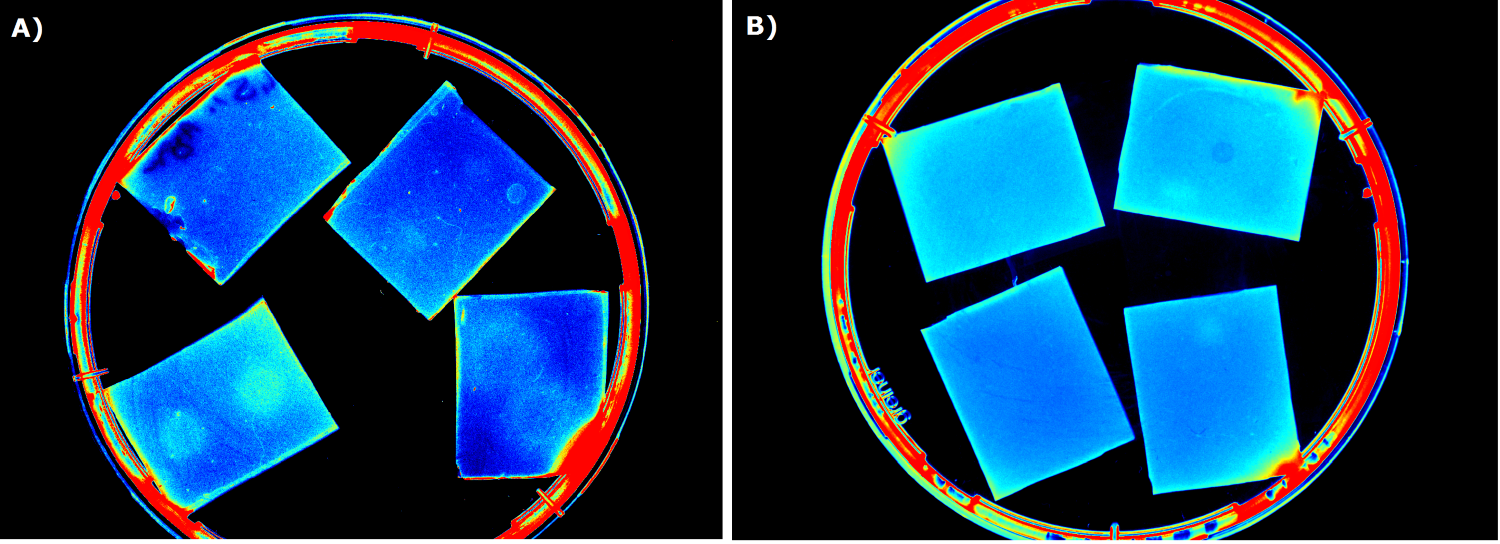

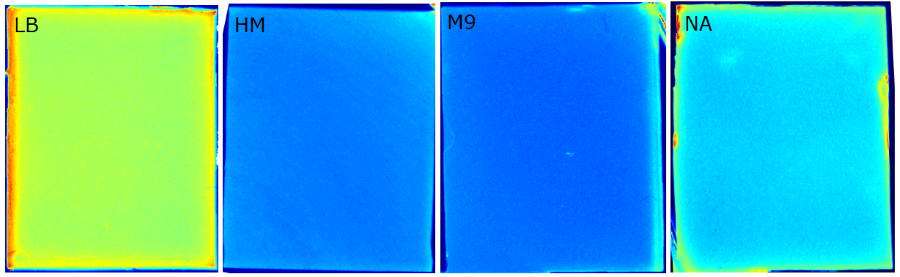

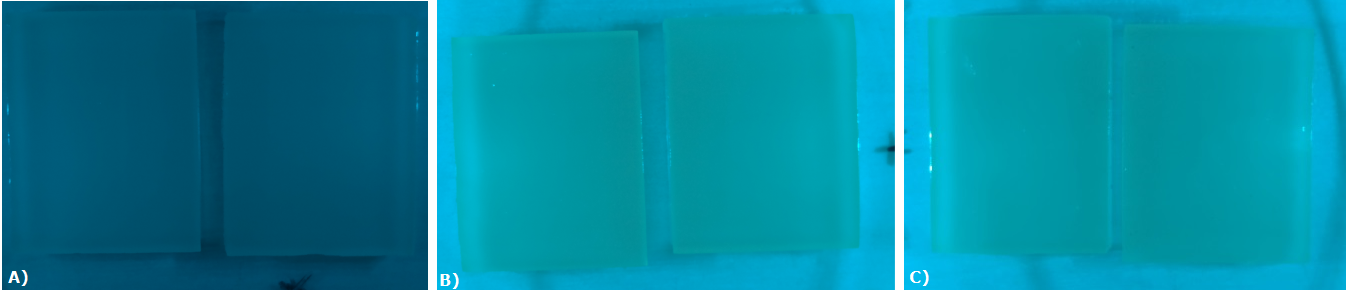

For the sensor chip manufacturing, agarose was preferred over agar, because of a uniform linkage that results in a better chip homogeneity. In addition, agarose reduced diffusion of the inducer molecules through the chip. A reduced diffusion is vital to observe distinct fluorescent spots on the sensor chips. | For the sensor chip manufacturing, agarose was preferred over agar, because of a uniform linkage that results in a better chip homogeneity. In addition, agarose reduced diffusion of the inducer molecules through the chip. A reduced diffusion is vital to observe distinct fluorescent spots on the sensor chips. | ||

=== Optimal chip configuration === | === Optimal chip configuration === | ||

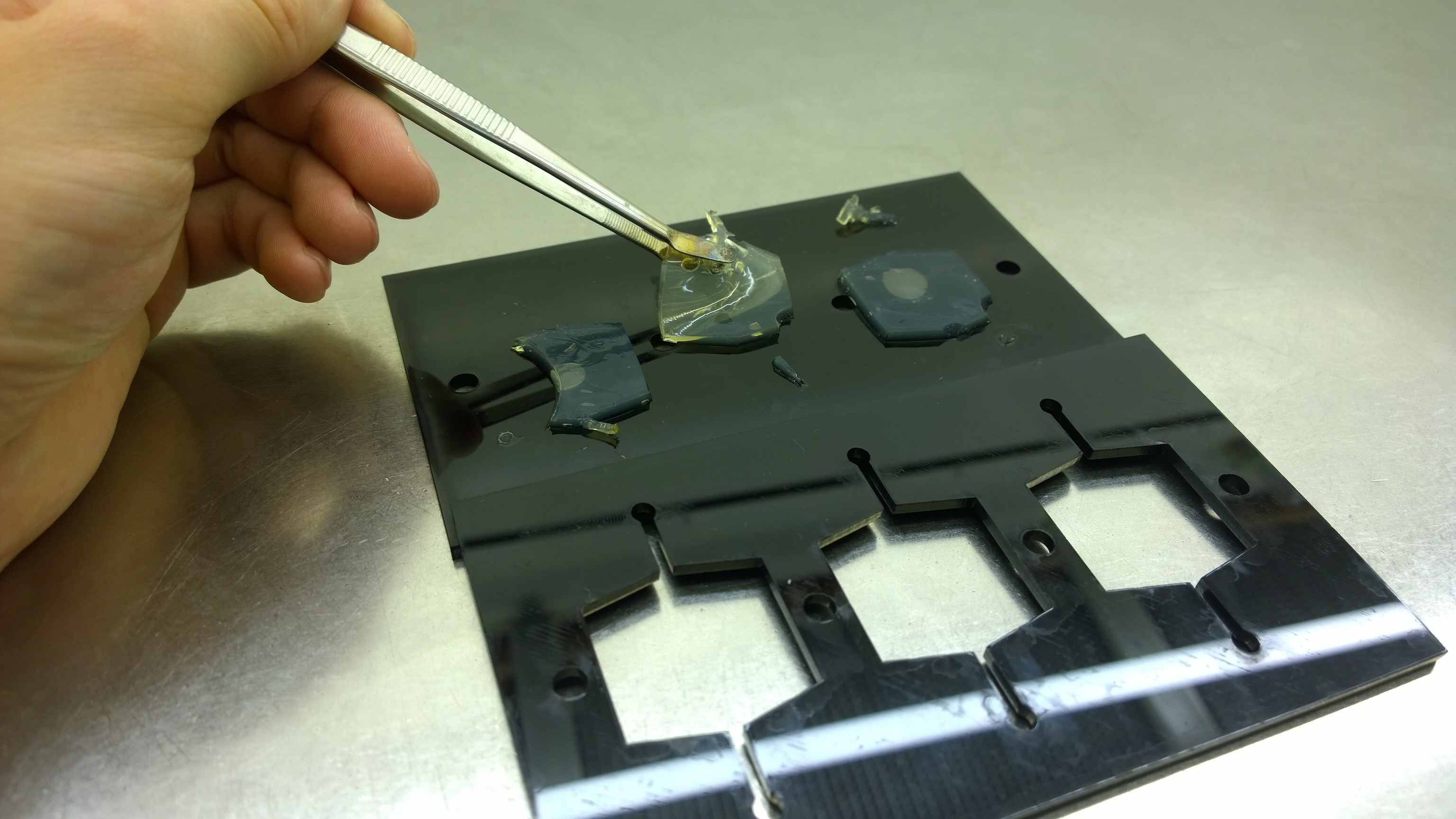

| - | {{Team:Aachen/FigureFloat|Aachen_2_chipform.jpg|title=Chips made using the closed mold|subtitle= | + | {{Team:Aachen/FigureFloat|Aachen_2_chipform.jpg|title=Chips made using the closed mold|subtitle=When injecting the agar into a closed mold we encounter problems due to frequent bubble formation.|left|width=500px}} |

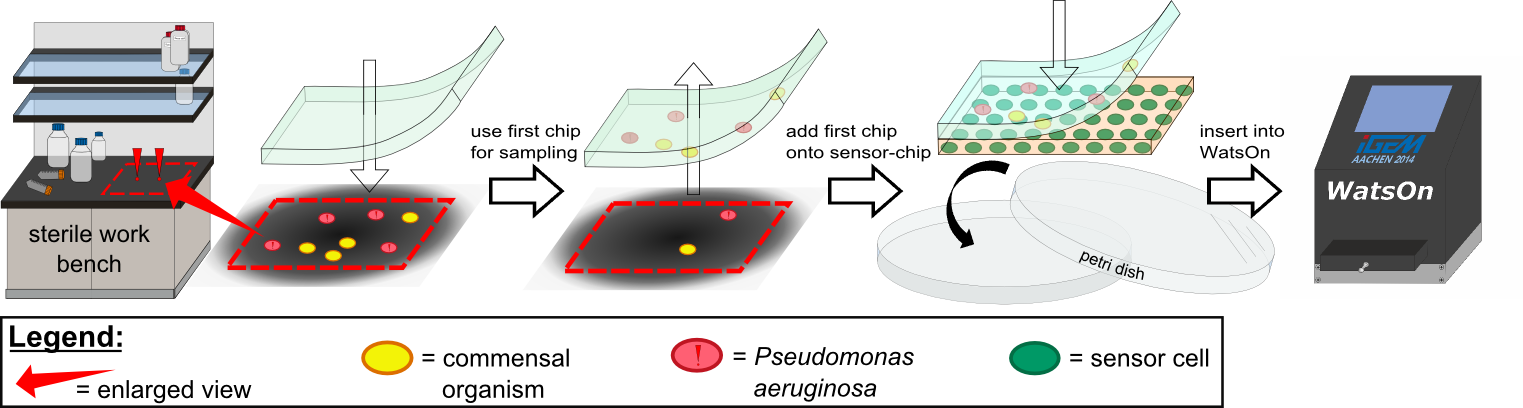

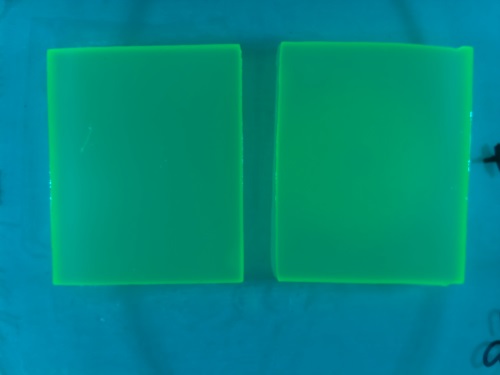

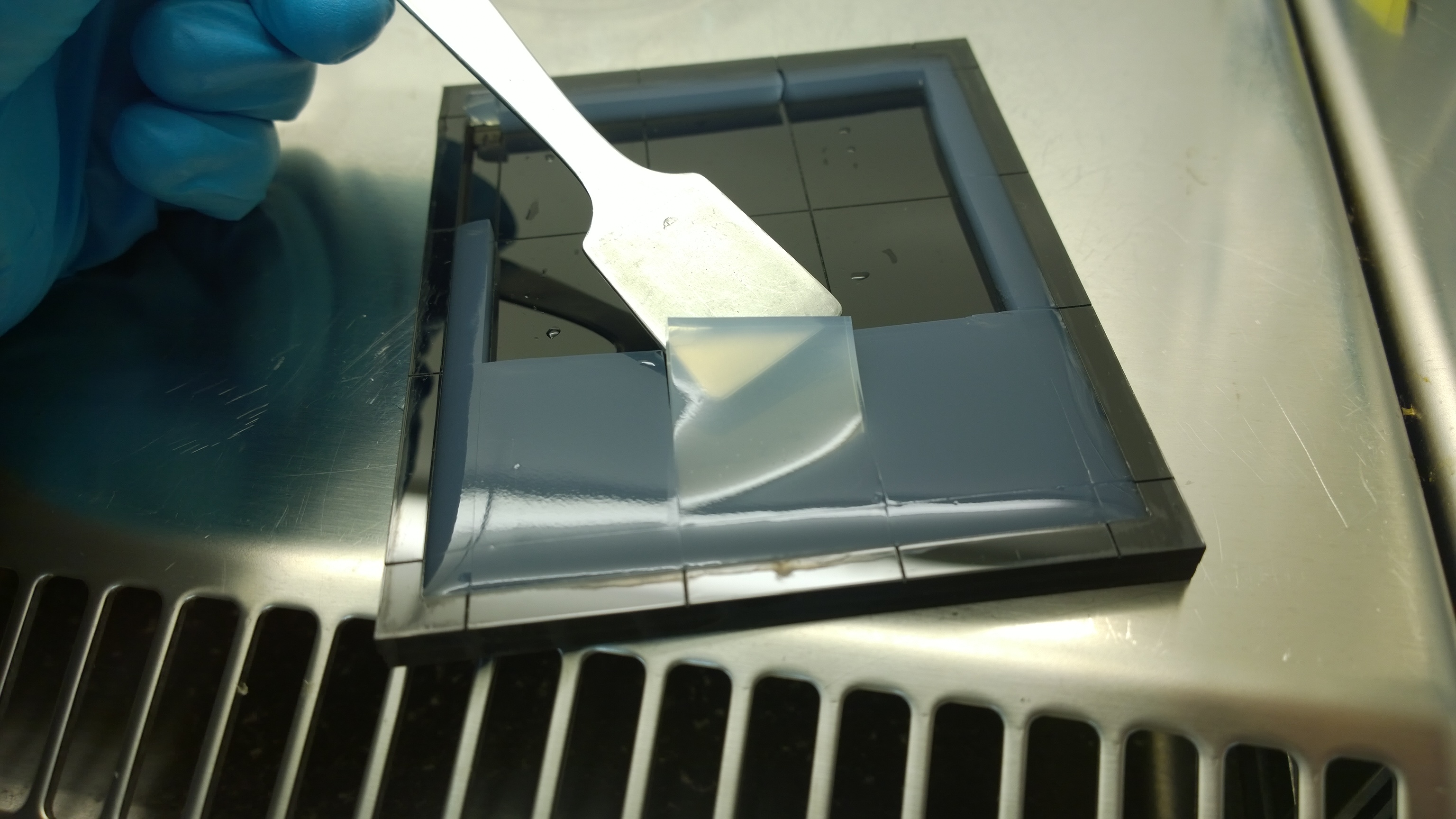

Several approaches were tested for the production of sensor chips with reproducible quality. The first approach was to cast every sensor chip individually. To achieve a plain chip surface (a requisite for high quality images), we casted the sensor chips between four microscope slides in an initial attempt. However, this approach was rejected, because the agar was too liquid and leaked from the microscope slides. In the second approach, we prepared a closed mold into which liquid agar was injected using a pipette, but we encountered a high number of bubbles in the chips when using this method. Bubbles in the sensor chips interfered in fluorescence evaluation. Finally, we used an open mold into which the agar was poured right after mixing with the sensor cells. After the agar solidified the chips were cut out along precast indentations in the casting mold. An advantage of the open mold was the ability to simultaneously produce nine sensor chips while the surface tension of the liquid agar ensured a plane chip surface. | Several approaches were tested for the production of sensor chips with reproducible quality. The first approach was to cast every sensor chip individually. To achieve a plain chip surface (a requisite for high quality images), we casted the sensor chips between four microscope slides in an initial attempt. However, this approach was rejected, because the agar was too liquid and leaked from the microscope slides. In the second approach, we prepared a closed mold into which liquid agar was injected using a pipette, but we encountered a high number of bubbles in the chips when using this method. Bubbles in the sensor chips interfered in fluorescence evaluation. Finally, we used an open mold into which the agar was poured right after mixing with the sensor cells. After the agar solidified the chips were cut out along precast indentations in the casting mold. An advantage of the open mold was the ability to simultaneously produce nine sensor chips while the surface tension of the liquid agar ensured a plane chip surface. | ||

{{Team:Aachen/FigureFloat|Aachen_Final_chipform.jpg|title=The finalized chip mold|subtitle=We found the above shown casting mold to be ideal for our purposes.|left|width=500px}} | {{Team:Aachen/FigureFloat|Aachen_Final_chipform.jpg|title=The finalized chip mold|subtitle=We found the above shown casting mold to be ideal for our purposes.|left|width=500px}} | ||

| - | |||

=== Induction of the sensor chip === | === Induction of the sensor chip === | ||

Revision as of 19:36, 17 October 2014

|

|

|

|

|

|

"

"