Development & Optimization

Medium

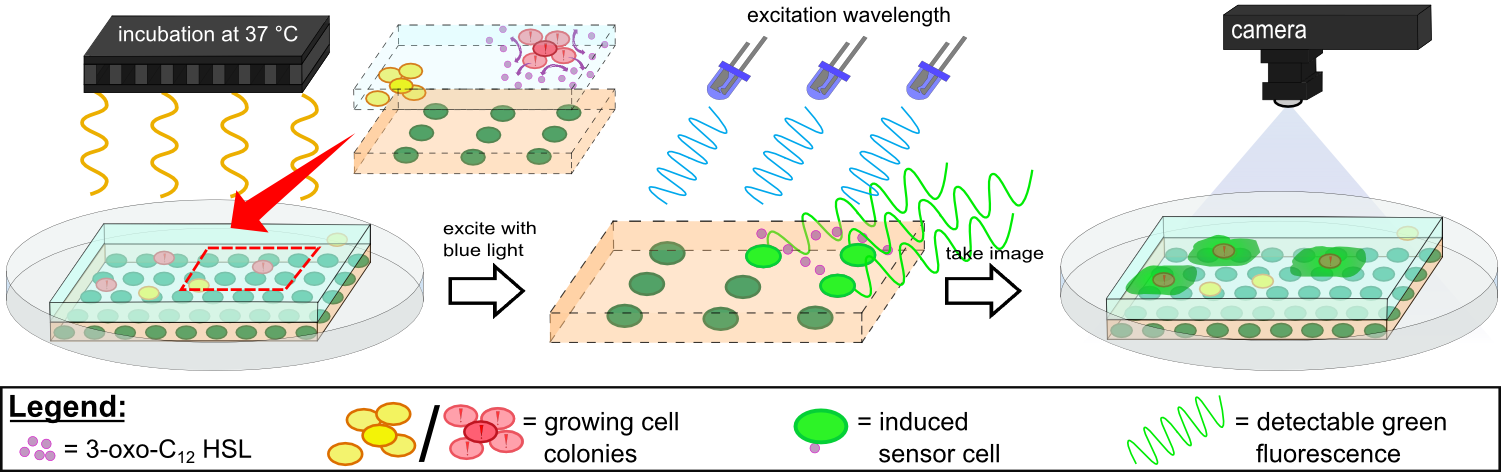

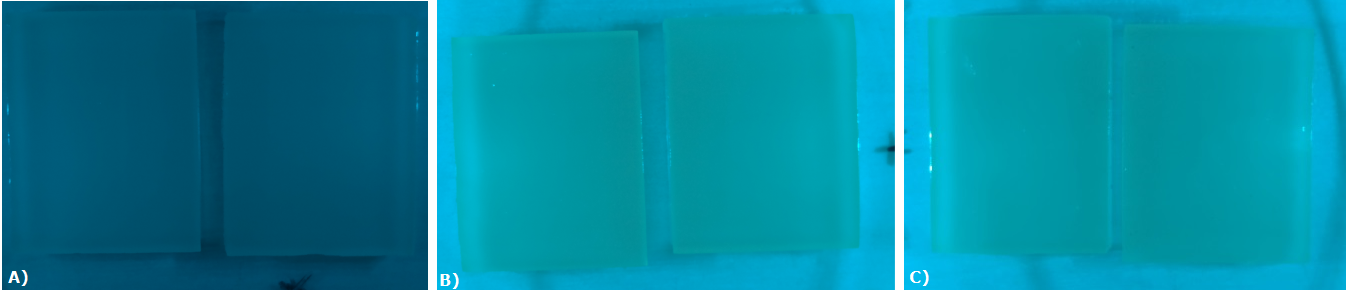

Prior to using our own device for detection of fluorescence emitted by the sensor chips we used equipment readily available in the lab. A Molecular Imager® Gel DocTM XR+ from BIO-RAD was available which uses UV and white light illuminators. However, only two different filters were available for the excitation ligth wavelength, which resulted in very limitted possibilities for the excitation of fluorescent molecules. For example, it was possible to detect the expression of iLOV in our sensor chips but the detection of GFP was not possible. It was thus determined that the Gel DocTM was not suitable for our project.

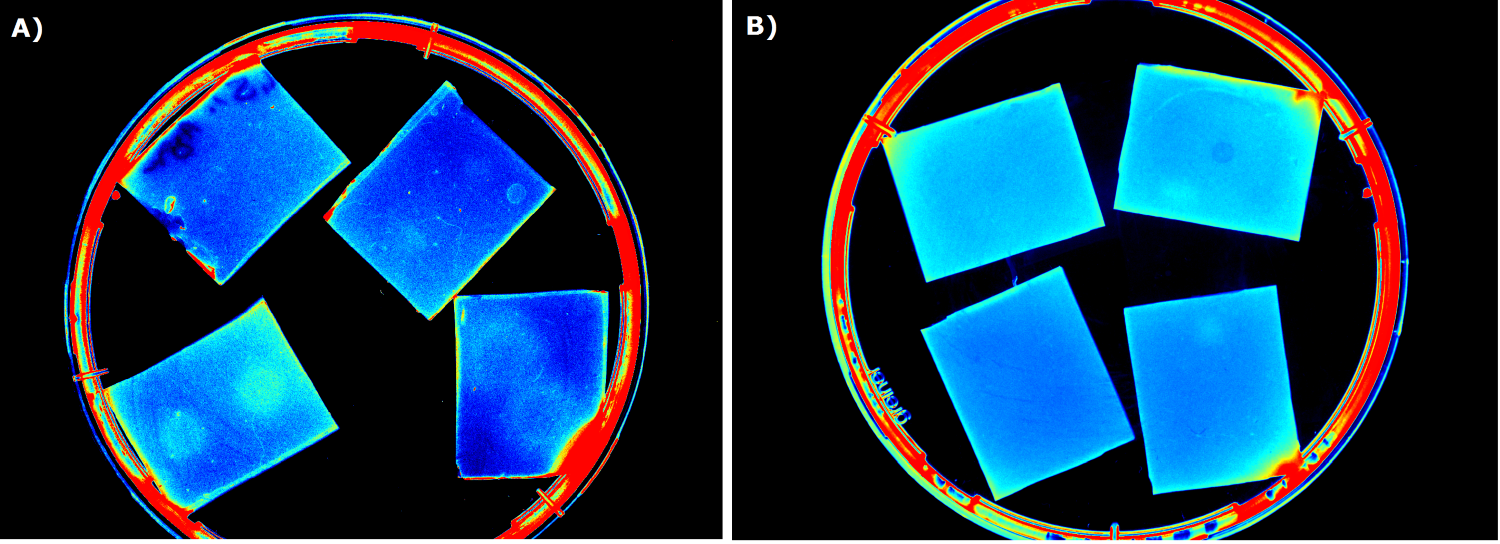

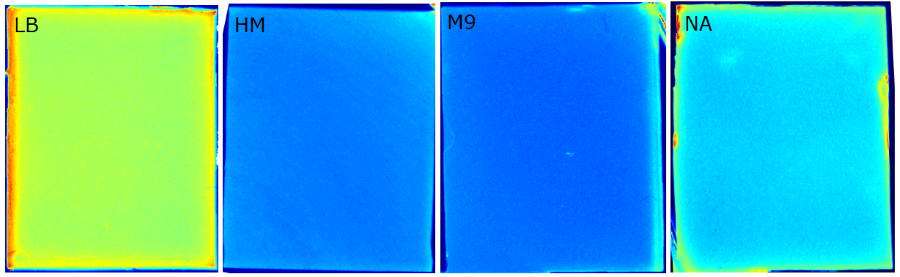

Regarding the medium used for our sensor chips, LB medium showed a high background fluorescence when exposed to UV light in the Gel Doc. Surprisingly, the background fluorescence resulting from the LB medium was too high to detect a signal emitted by our sensor cells. Hence, minimal media (NA, M9, Hartman (HM)) was used to minimize background fluorescence, but this approach resulted in less to no growth of our sensor cells.

In our device WatsOn, optimized wavelengths of 450 nm and 480 nm were used for excitation of iLOV and GFP, respectively. When exposed to either excitation wavelength TB medium, which is basically an improved LB medium and highly supports cell growth, showed strong background fluorescence in our own device. High background fluorescence was also observed for TB medum when using the Gel Doc. In contrast to the Gel Doc LB medium showed minimal fluorescence in our device WatsOn and no difficulties in cultivation of our Cellocks were observed. Because of the reduced fluorescence compared to TB medium when using Watson for sensor chip evaluation and because of sufficient cultivation conditions for our 'Cellocks LB medium was chosen over TB mediium for sensor chip manufacturing.

Further experiments were conducted to test long-time storage of the sensor chips. Storage at -20 °C resulted in the loss of our sensor cells. Adding 5-10% (v/v) glycerol ensured survival of the sensor cells, but resulted in an expression stop of fluorescence proteins. Thus, the idea of long time storage of the sensor chips had to be passed on. However, it was possible to store ready-to-use sensor chips for 2 days at 4 °C when using LB medium and storage for 5 days was possible with chips made from TB medium.

Agar Concentration

For the sensor chip manufacturing, a concentration of 1.5 % agarose was found to be optimal. When agarose concentrations below 1.5 % (w/v) were used the sensor chips were easily damaged and were not transportable. Agar concentrations above 1.5 % (w/v) had to be avoided, because the agarose started to solidify before it could be poured into the chip casting mold.

Agarose was chosen above agar, because of more even linkage resulting in a better chip homogenity. In addition, agarose reduced diffusion of inducer molecules through the chip. A reduced diffusion was desired in order to achieve distinct fluorescent spots on the sensor chips.

Chip Form

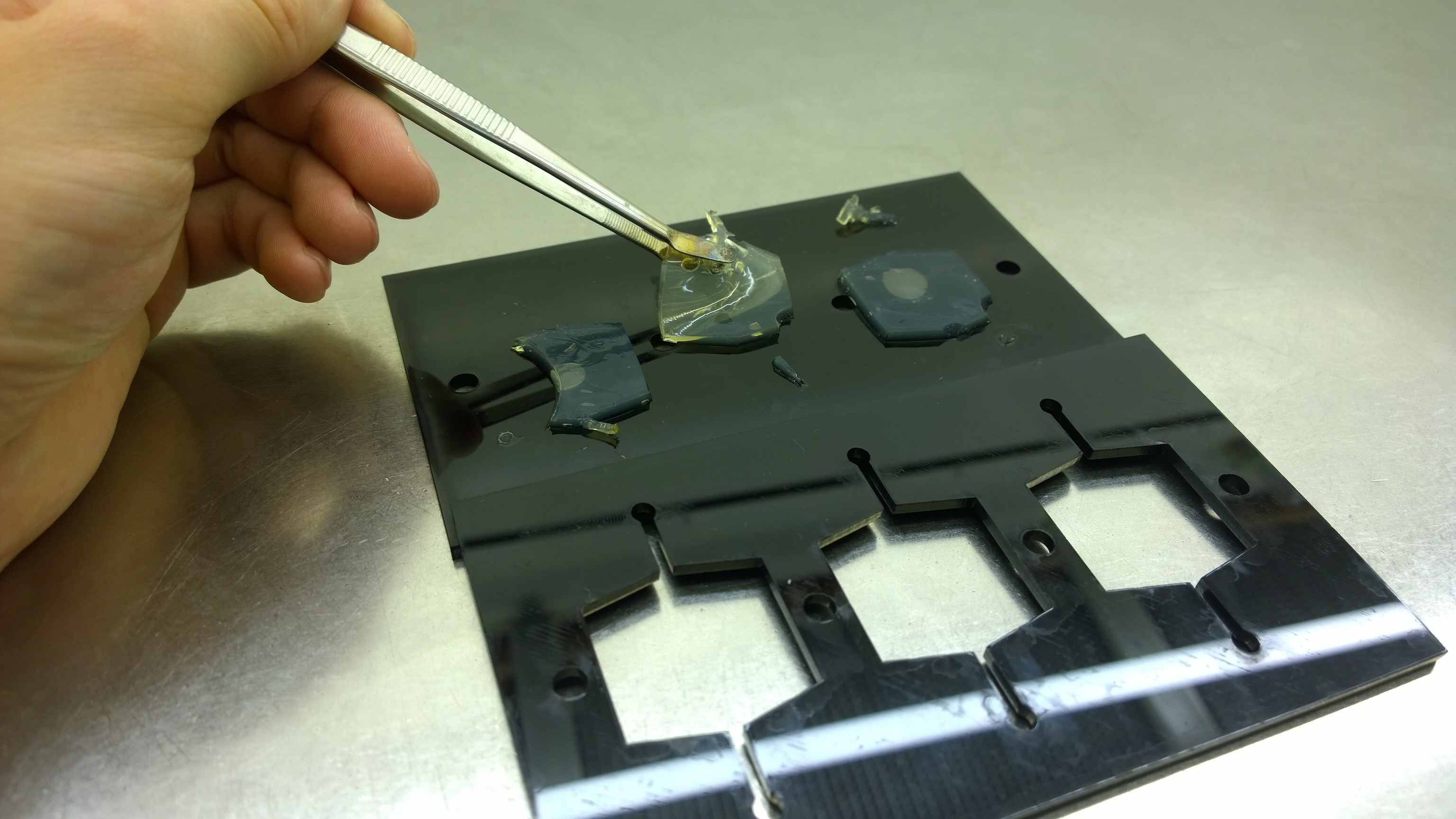

Various approaches were tried for production of sensor chips with reproducable quality. The first approach was to cast every sensor chip individually. In order to achieve a plain chip surface, which was required for high quality images, we tried to cast the sensor chips between four microscope slides. This approach had to be rejected, because the agar was too liquid. In a second try, we produced a closed mold into which liquid agar was injected using a pipette, but we encountered a high number of bubbles in the chips when using this method. Bubbles in the sensor chips resulted in problems during fluorescence evalutaion.

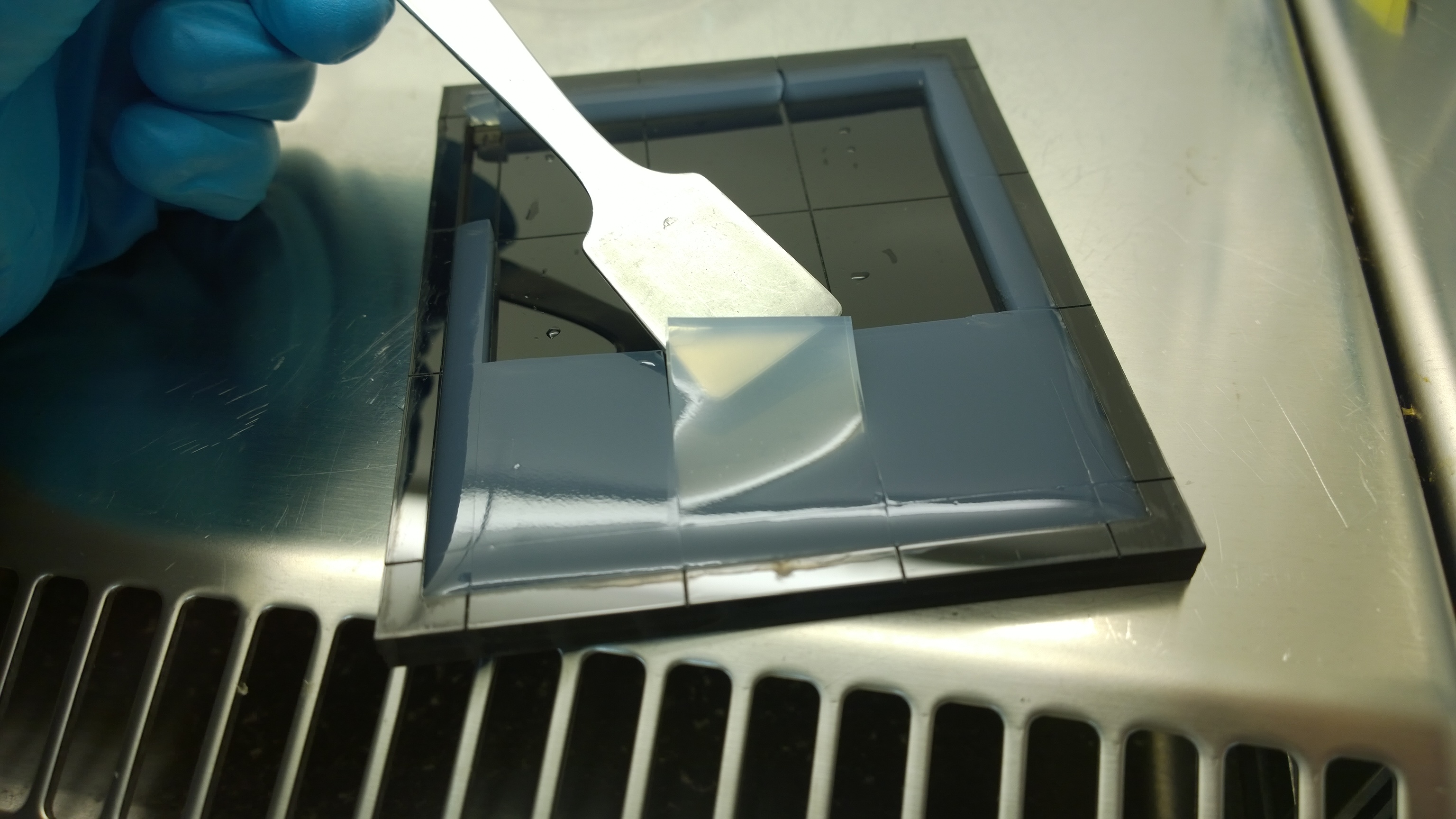

Finally, we used an open mold into which the agar was poured right after mixing with the sensor cells. When the agar had solidified the chips were cut out along precast indentations in the casting mold. An advantage of the open mold was the ability to simultaneously produce nine sensor chips while the surface tension of the liquid agar ensured a plane chip surface.

Induction

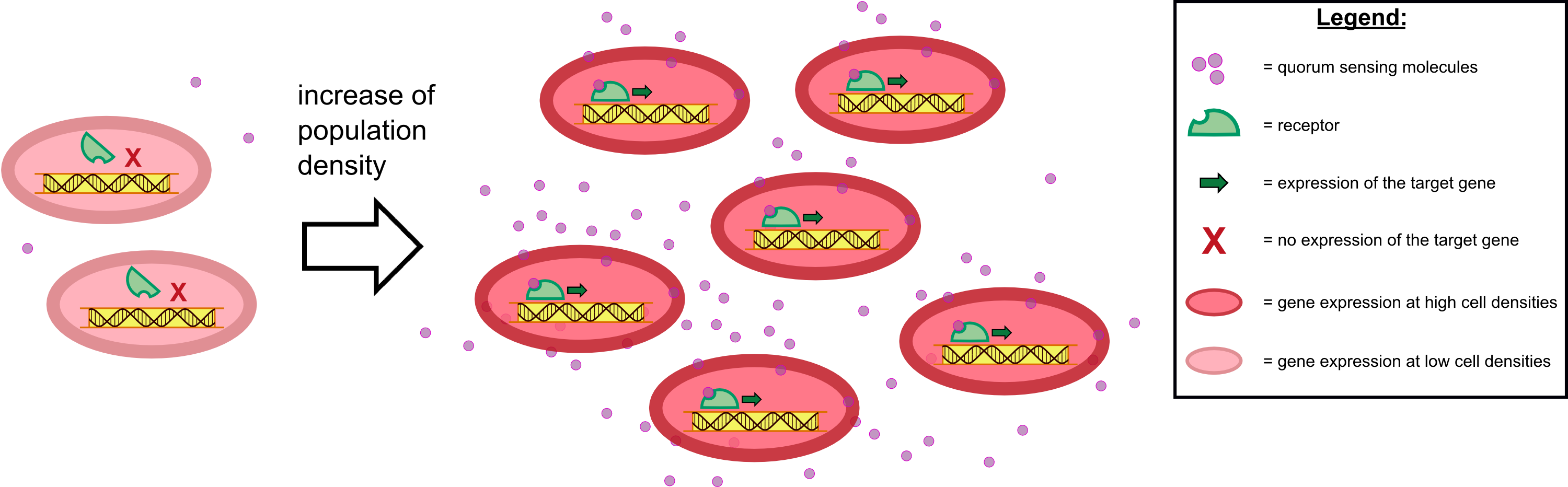

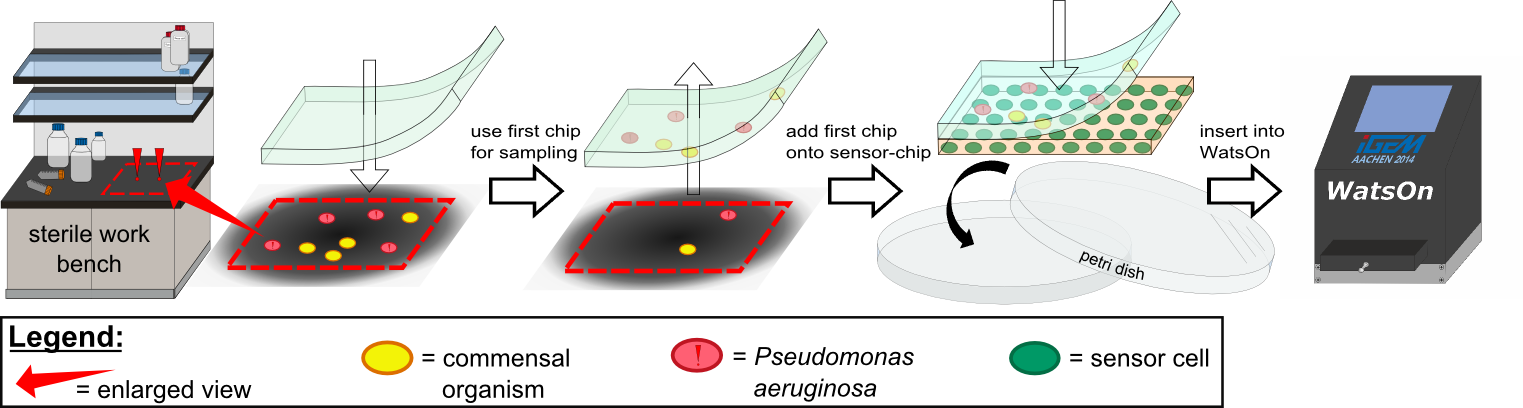

For artificially induction of our molecular detection constructs we simluated the presence of P. aeruginosa by use of IPTG or 3-oxo-C12 HSL.

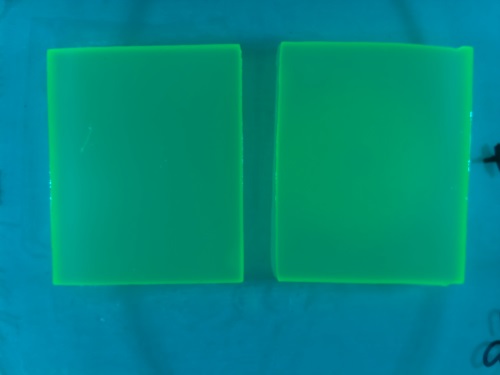

A minimal pipetting volume was desired for induction, because initial experiments showed that diffusion of the inducers through the chip hindered formation of distinct spots on the chips. Due to the pipetts available the lowest volume we could pipett was limitted to 0.2 µL .

Sensor cells based on E. coli BL21, which incorporated the K1319042 construct were able to detect IPTG concentrations down to 1 mM (0.2 µL), so were sensor cells based on E. coli BL21, which incorporated the REACh constructs.

Sensor cells based on E. coli BL21, which incorporated the [http://parts.igem.org/Part:BBa_K131026 K131026] construct were able to detect HSL concentrations down to 500 µg/mL (0.2 µL). Further more, detection of growing Pseudomonas aeruginosa cells based on secreted HSLs was possible using the [http://parts.igem.org/Part:BBa_K131026 K131026] construct. A detailed description including pictures of the experiments leading to the just mentioned findings can be found in the Achievements section.

|

"

"