Team:Aachen/Project/2D Biosensor

From 2014.igem.org

(→Development & Optimization) |

Aschechtel (Talk | contribs) (→Chip Form) |

||

| Line 122: | Line 122: | ||

=== Chip Form === | === Chip Form === | ||

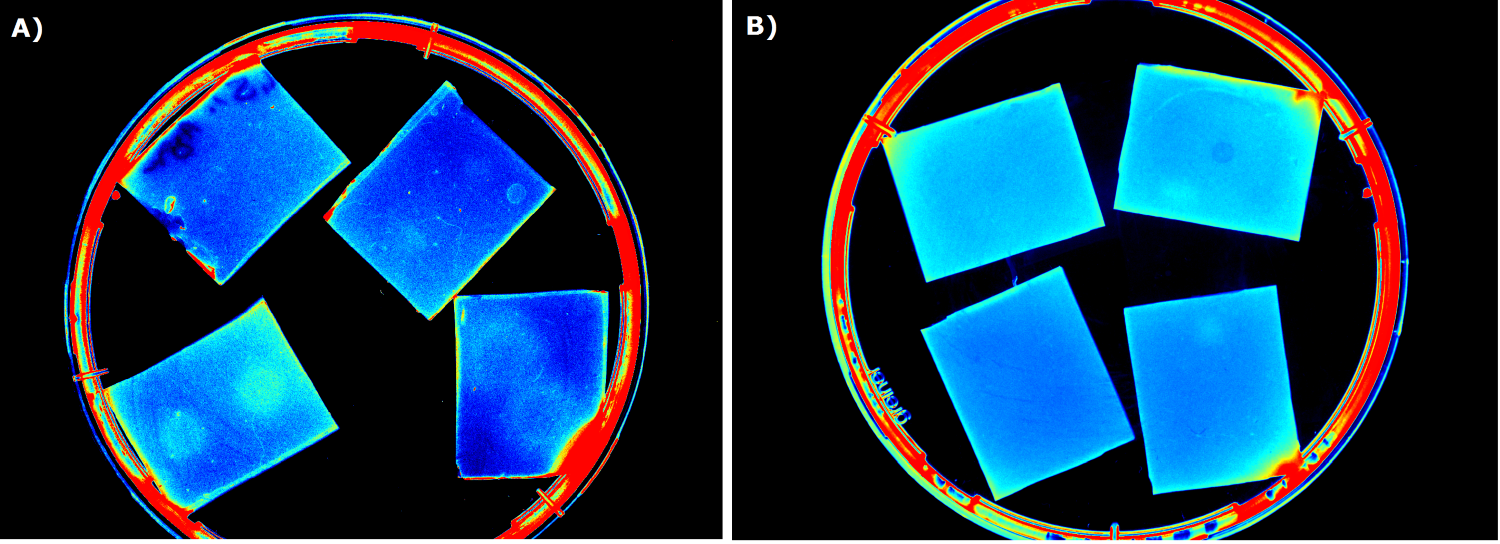

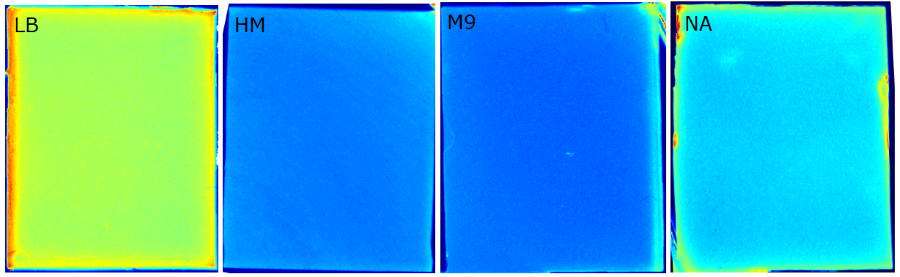

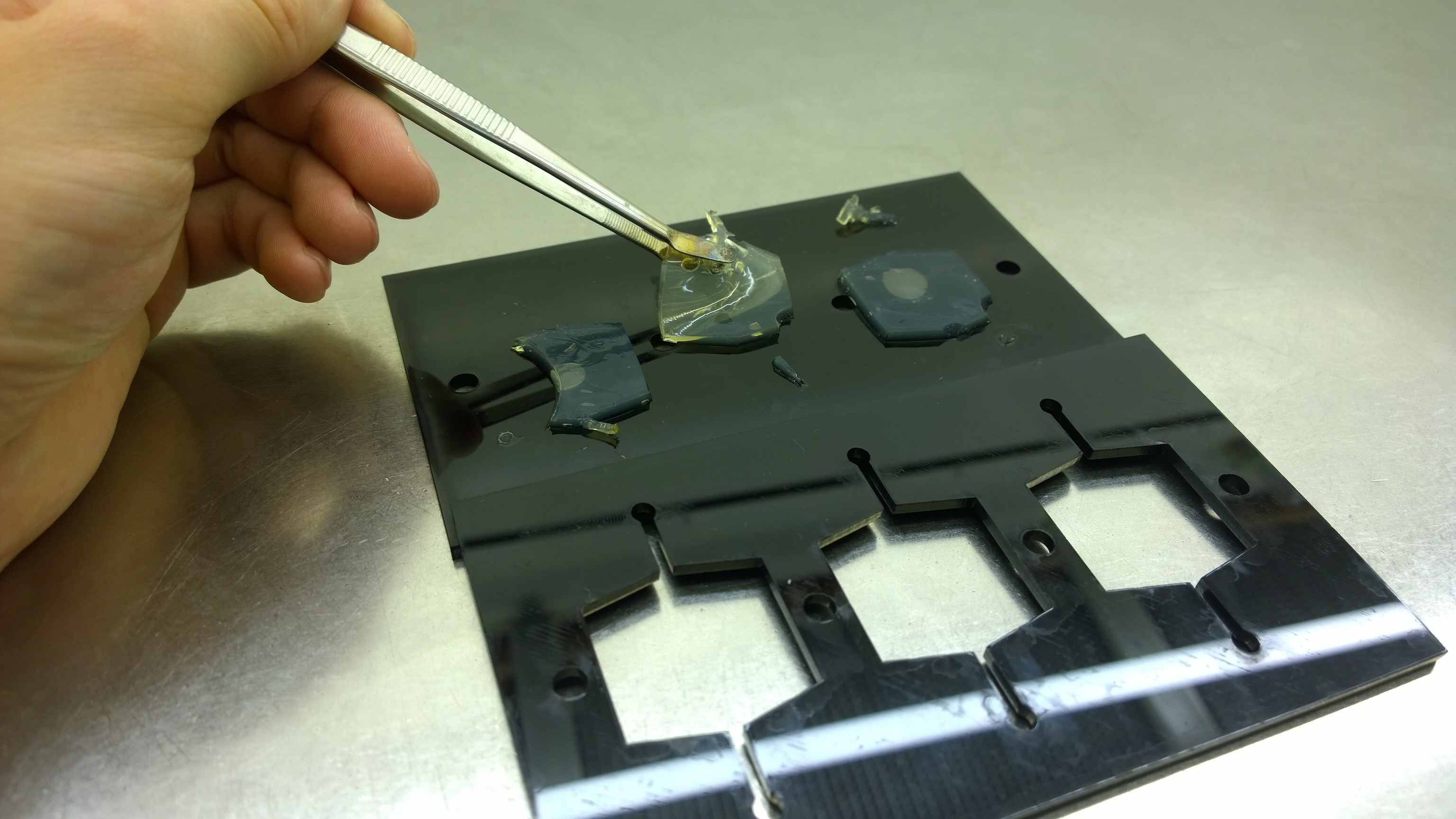

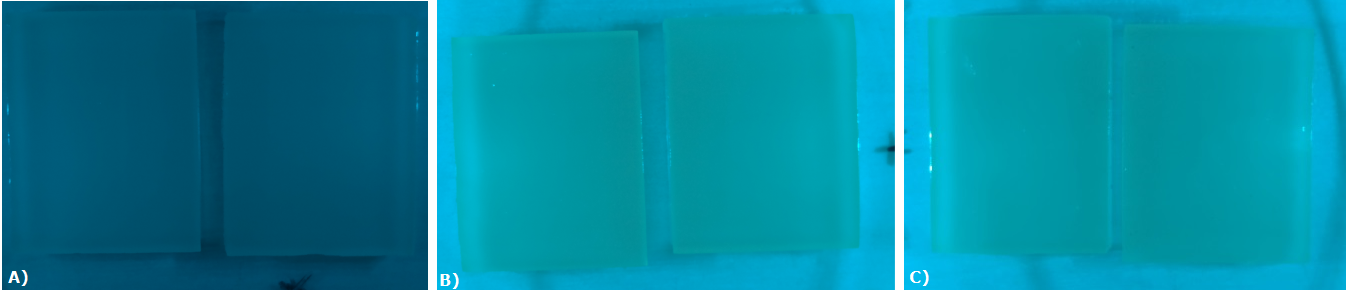

Various approaches were tried for production of sensor chips with reproducable quality. The first approach was to cast every sensor chip individually. In order to achieve a plain chip surface, which was required for high quality images, we tried to cast the sensor chips between four microscope slides. This approach had to be rejected, because the agar was too liquid. In a second try, we produced a closed mold into which liquid agar was injected using a pipette, but we encountered a high number of bubbles in the chips when using this method. Bubbles in the sensor chips resulted in problems during fluorescence evalutaion. | Various approaches were tried for production of sensor chips with reproducable quality. The first approach was to cast every sensor chip individually. In order to achieve a plain chip surface, which was required for high quality images, we tried to cast the sensor chips between four microscope slides. This approach had to be rejected, because the agar was too liquid. In a second try, we produced a closed mold into which liquid agar was injected using a pipette, but we encountered a high number of bubbles in the chips when using this method. Bubbles in the sensor chips resulted in problems during fluorescence evalutaion. | ||

| - | + | {{Team:Aachen/Figure|Aachen_2_chipform.jpg|title=Chips out of the closed Mold|width=900px}} | |

Finally, we used an open mold into which the agar was poured right after mixing with the sensor cells. When the agar had solidified the chips were cut out along precast indentations in the casting mold. An advantage of the open mold was the ability to simultaneously produce nine sensor chips while the surface tension of the liquid agar ensured a plane chip surface. | Finally, we used an open mold into which the agar was poured right after mixing with the sensor cells. When the agar had solidified the chips were cut out along precast indentations in the casting mold. An advantage of the open mold was the ability to simultaneously produce nine sensor chips while the surface tension of the liquid agar ensured a plane chip surface. | ||

| - | + | {{Team:Aachen/Figure|Aachen_final_chipform.jpg|title=Final Chip Mold|width=900px}} | |

=== Induction === | === Induction === | ||

Revision as of 13:13, 16 October 2014

|

|

|

|

|

"

"