Team:RHIT/Sustainability

From 2014.igem.org

| Line 126: | Line 126: | ||

<img src="http://i1265.photobucket.com/albums/jj502/bauhand/Sustdiagram_zps66e7d648.png" float="left"/> | <img src="http://i1265.photobucket.com/albums/jj502/bauhand/Sustdiagram_zps66e7d648.png" float="left"/> | ||

| - | + | <p>In the production of our Victor the Vector device, our team used a 3D printer to create parts for the device. This 3D printer used PLA (polylactic acid) plastic to print the parts.</p> | |

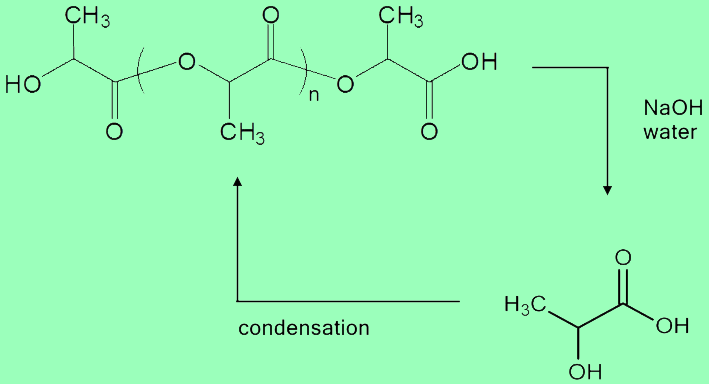

| + | <p>PLA is a biodegradable polyester that is developed from various biological sources such as corn starch. PLA can be used for several plastic products such as cups, packaging material, and even as various parts of medical implants. It is a desirable replacement for several other plastics that may not be able to degrade.</p> | ||

| + | <p>Due to the fact that PLA is produced from biological sources, it is reasonable that it could be broken down and recycled into the environment. Since PLA is a polymer of lactic acid, hydrolysis of the polymer will degrade it back into lactic acid. Our team decided to use the scrap pieces of PLA from the 3D printing, and convert it back into lactate, which could then be used in the media for our <i>E. coli</i> cells.</p> | ||

| + | <p>This was done by a simple hydrolysis reaction, adding base to the polymer to break it down, then neutralizing the solution with base and filtering. The reaction is shown below along with the protocols used to degrade and characterize the solution.</p> | ||

<br> | <br> | ||

| + | |||

| + | <img src="http://i1265.photobucket.com/albums/jj502/bauhand/PLAreaction_zps8c72d38c.png" float="right"/> | ||

<br> | <br> | ||

Revision as of 17:14, 7 August 2014

"

"