Team:Aachen/Notebook/Wetlab/October

From 2014.igem.org

(Difference between revisions)

Aschechtel (Talk | contribs) (→15th) |

(→3rd) |

||

| (8 intermediate revisions not shown) | |||

| Line 79: | Line 79: | ||

== 1st == | == 1st == | ||

* Prepartations for sensor-chip production the following day (2014-10-02) was done accoringly to the [https://2014.igem.org/Team:Aachen/Notebook/Protocols/detection sensor-chip manufacturing protocol]: | * Prepartations for sensor-chip production the following day (2014-10-02) was done accoringly to the [https://2014.igem.org/Team:Aachen/Notebook/Protocols/detection sensor-chip manufacturing protocol]: | ||

| - | ** At 18:30 we prepared over-night cultures from K1319042, B0015 and K131026 by inoculating 250 ml Erlenmeyer flasks each containing 50 ml LB medium . The flasks were incubated for ~12 hours at | + | ** At 18:30 we prepared over-night cultures from K1319042, B0015 and K131026 by inoculating 250 ml Erlenmeyer flasks each containing 50 ml LB medium . The flasks were incubated for ~12 hours at 37°C on a shaker. |

== 2nd == | == 2nd == | ||

| Line 87: | Line 87: | ||

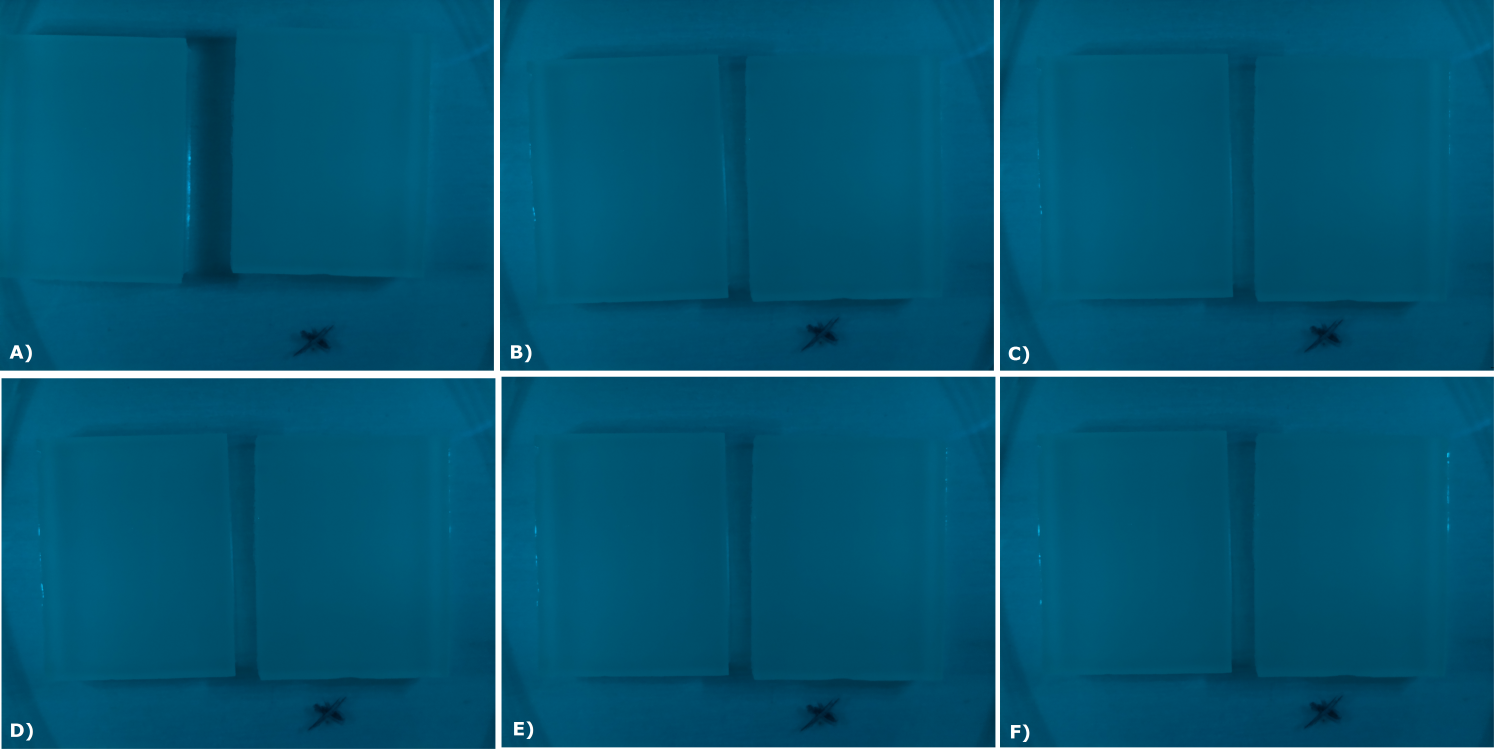

* Production of sensor-chips was done accordingly to [https://2014.igem.org/Team:Aachen/Notebook/Protocols/detection sensor-chip manufacturing protocol]. Briefly: | * Production of sensor-chips was done accordingly to [https://2014.igem.org/Team:Aachen/Notebook/Protocols/detection sensor-chip manufacturing protocol]. Briefly: | ||

| - | ** At 10:00 we prepared 150 ml 1.5 | + | ** At 10:00 we prepared 150 ml 1.5% (w/v) LB+agarose solution. The LB+agarose solution was autoclaved and subsequently tempered to 45°C. Precultures (50 ml each) of K1319042, B0015 and K131026 were spun down at 3000 g for 10 min at 21°C and re-suspended in 1 ml pretempered (21°C) LB medium. The re-suspended cultures were mixed with 50 ml LB+agarose and poured onto three sensor-chip-templates (one template per culture). Sensor chips were cut out from the template and incubated at 37°C for 1 h. |

** K1319042 and B0015 were induced with 0.2 µl IPTG (100 mM) subsequently to incubation and K131026 was induced with 0.2 µl homoserinlacton stock solution (500 µg/ml) 30 minutes after induction of the K1319042 and B0015. The induced sensor-chips were read out every 30 minutes for 180 minutes in total. An additional readout was conducted 285 minutes post induction. The readout was done at 450 nm and 480 nm wavelength. | ** K1319042 and B0015 were induced with 0.2 µl IPTG (100 mM) subsequently to incubation and K131026 was induced with 0.2 µl homoserinlacton stock solution (500 µg/ml) 30 minutes after induction of the K1319042 and B0015. The induced sensor-chips were read out every 30 minutes for 180 minutes in total. An additional readout was conducted 285 minutes post induction. The readout was done at 450 nm and 480 nm wavelength. | ||

<center> | <center> | ||

| - | {{Team:Aachen/Figure|Aachen_02_10_2014_B0015_serie.png|title=Sensor Chips with B0015 in NEB in LB (480 nm): first try with final device|subtitle=Sensor chips with B0015 in NEB in LB medium with 1,5 | + | {{Team:Aachen/Figure|Aachen_02_10_2014_B0015_serie.png|title=Sensor Chips with B0015 in NEB in LB (480 nm): first try with final device|subtitle=Sensor chips with B0015 in NEB in LB medium with 1,5% agarose, right chip induced. A) befor induction with 0.2 µl of 100 mM IPTG B) 0.5 h after induction C) 1 h after induction D) 1.5 h after induction E) 2 h after induction F) 2.5 h after induction|width=900px}} |

</center> | </center> | ||

| Line 140: | Line 140: | ||

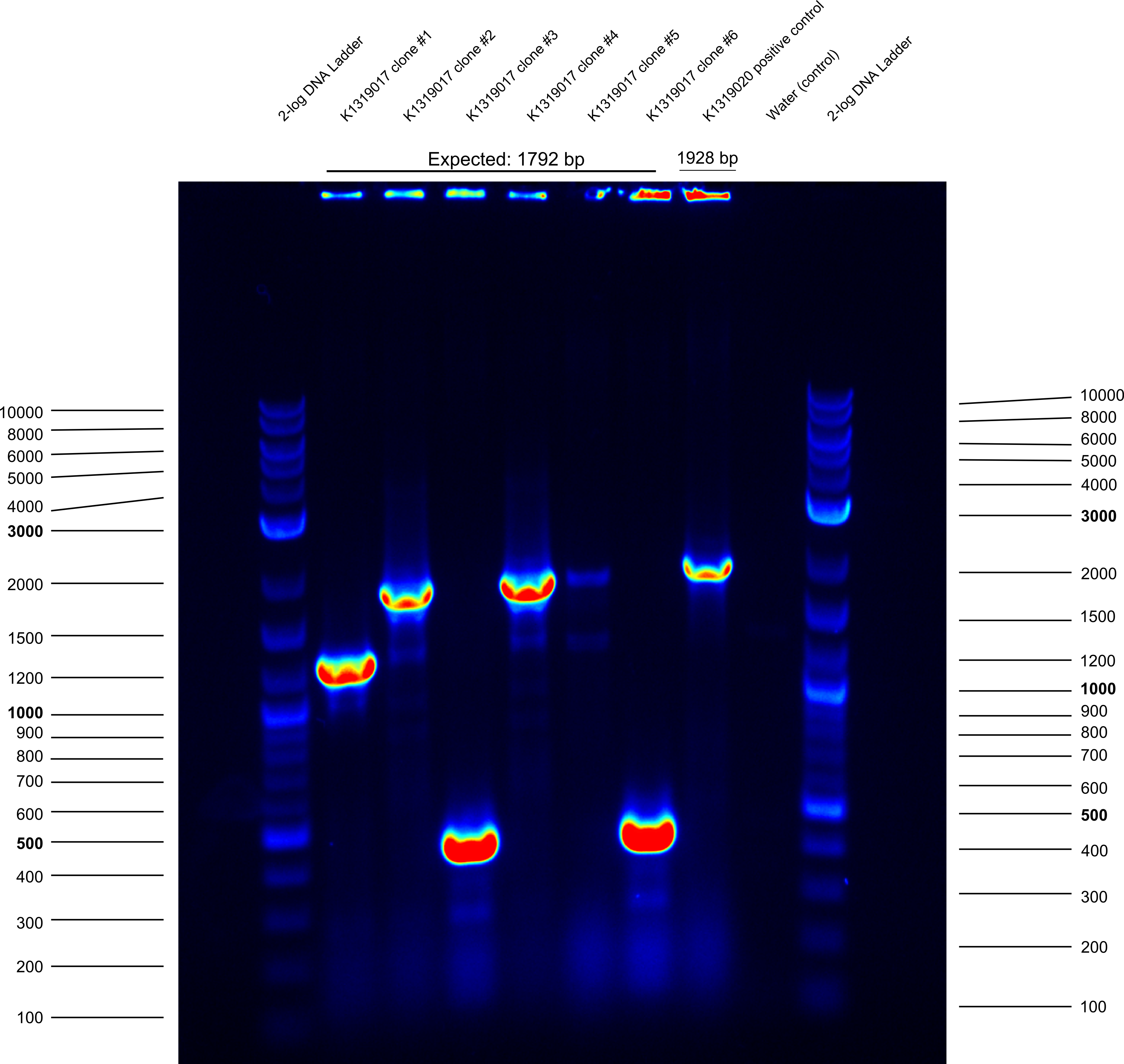

* did plasmid prep and cryo of clones #2 and #4 of K1319017 | * did plasmid prep and cryo of clones #2 and #4 of K1319017 | ||

| - | * new plasmid backbone of pSB1C3 was made using the [http://parts.igem.org/Help:Protocols/Linearized_Plasmid_Backbones | + | * new plasmid backbone of pSB1C3 was made using the [http://parts.igem.org/Help:Protocols/Linearized_Plasmid_Backbones Standard Protocol]. |

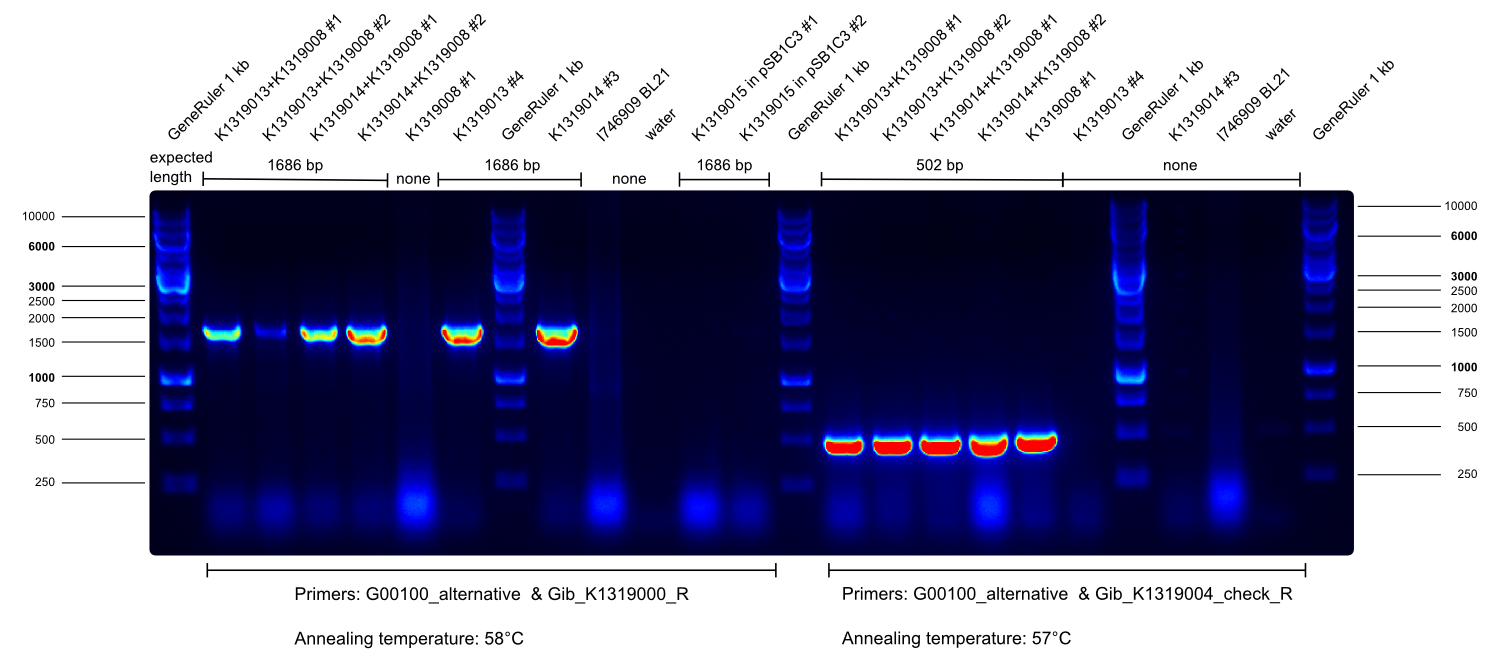

* transformation of K1319008 clone #1 (from BL21) and K1319013 into BL21 (two plasmids in one cell). | * transformation of K1319008 clone #1 (from BL21) and K1319013 into BL21 (two plasmids in one cell). | ||

| Line 146: | Line 146: | ||

* transformation of K1319008 clone #1 (from BL21) and k1319014 into BL21 (two plasmids in one cell). | * transformation of K1319008 clone #1 (from BL21) and k1319014 into BL21 (two plasmids in one cell). | ||

| - | * OD measurements of three biological triplicates from ''E. coli'' BW21 113, ''P. putida'' and ''S. cerevisiae''. Measurement as an analytic triplicate in the spectrophotometer (absorbance and transmission) and our own OD/F | + | * OD measurements of three biological triplicates from ''E. coli'' BW21 113, ''P. putida'' and ''S. cerevisiae''. Measurement as an analytic triplicate in the spectrophotometer (absorbance and transmission) and our own OD/F Device. |

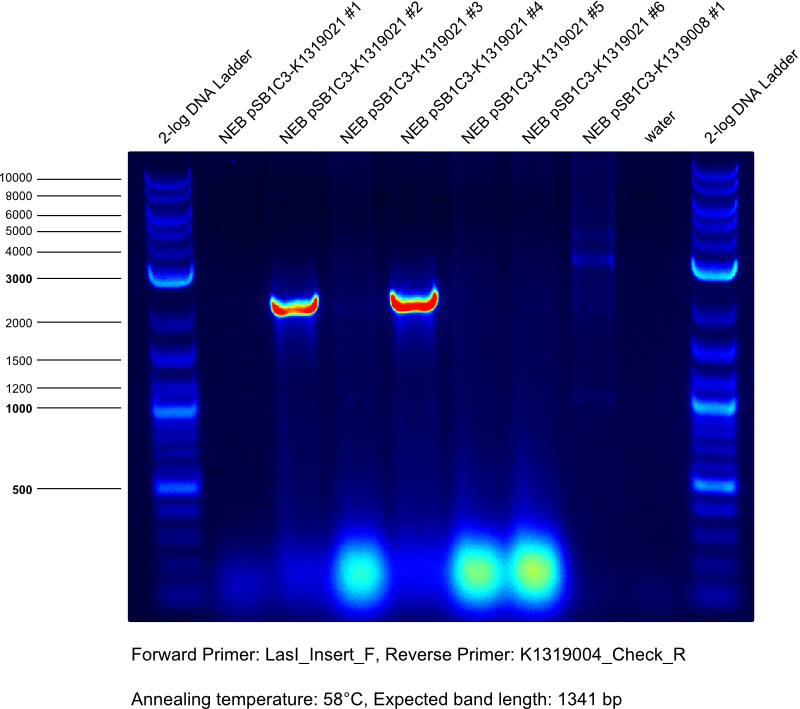

* Gibson assembly of K1319021 | * Gibson assembly of K1319021 | ||

| Line 152: | Line 152: | ||

** template Insert: LasI gene synthesis | ** template Insert: LasI gene synthesis | ||

| - | * At 19:00 we measured OD (our OD-device), absorption (spectrophotometer) and transmission (spectrophotometer) for 19 diltuions in the range of 2.5-100 | + | * At 19:00 we measured OD (our OD-device), absorption (spectrophotometer) and transmission (spectrophotometer) for 19 diltuions in the range of 2.5-100% from yeast (''Saccharomyces cerevisiae'') and ''P. putida'' liquid cultures. Measurements were conducted in biological as well as technical triplicates. Aim of this experiment was the comparison of our OD-device to commonly used devices in terms of OD determination. |

* Prepartations for sensor-chip production the following day (2014-10-04) were done accordingly to the [https://2014.igem.org/Team:Aachen/Notebook/Protocols/detection sensor-chip manufacturing protocol]: | * Prepartations for sensor-chip production the following day (2014-10-04) were done accordingly to the [https://2014.igem.org/Team:Aachen/Notebook/Protocols/detection sensor-chip manufacturing protocol]: | ||

| - | ** At 22:00 we prepared over-night cultures from B0015, K1319017 and K131026 by inoculating 250 mL Erlenmeyer flasks each containing 50 mL LB medium for sensor-chip manufacturing the next day. The flasks were incubated for ~12 hours at | + | ** At 22:00 we prepared over-night cultures from B0015, K1319017 and K131026 by inoculating 250 mL Erlenmeyer flasks each containing 50 mL LB medium for sensor-chip manufacturing the next day. The flasks were incubated for ~12 hours at 37°C on a shaker. |

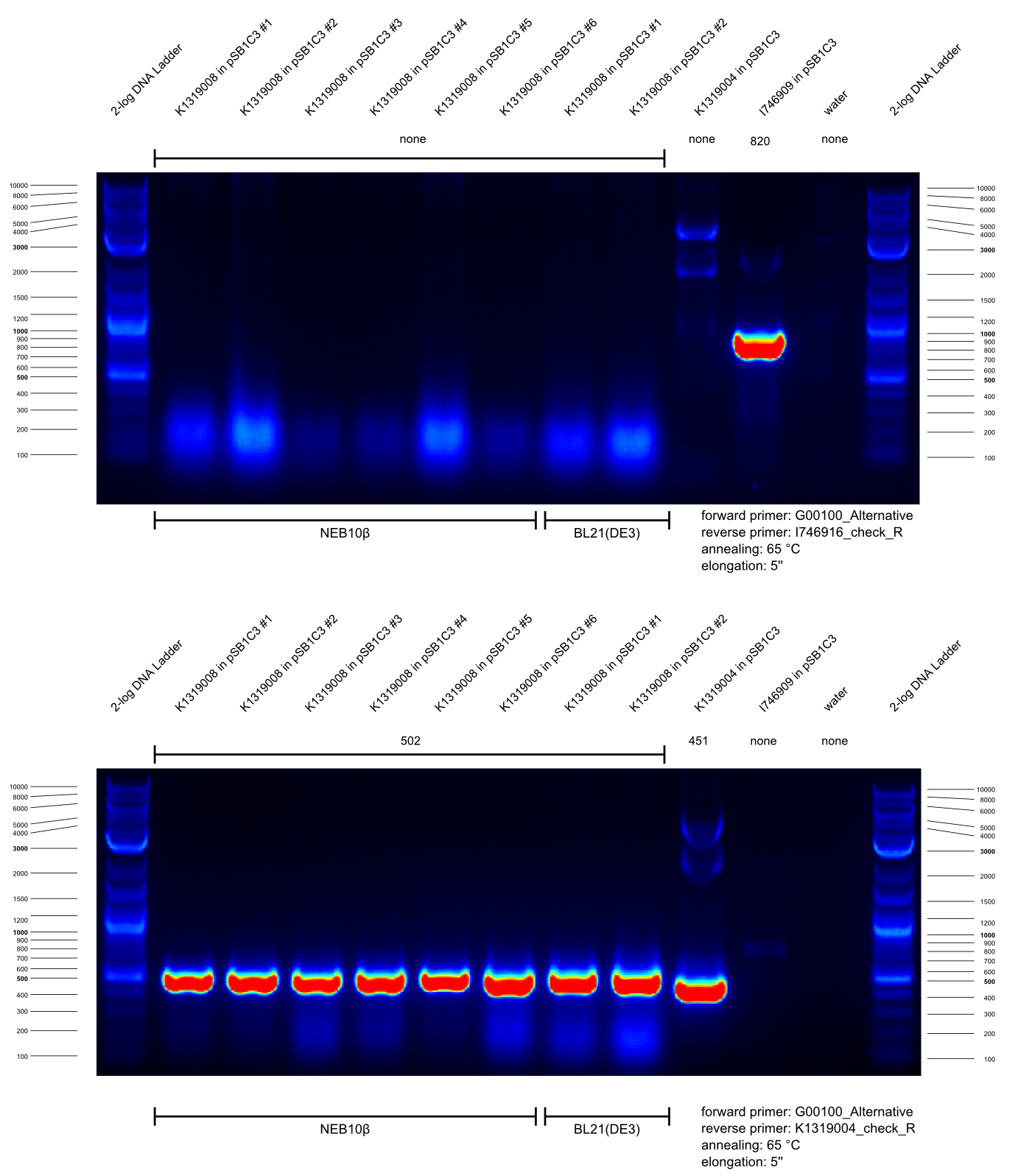

* Our BioBrick K1319021 enables expression of the TEV protease inducible by the autoinducers of ''Pseumomonas aeruginosa''. In order to construct this BioBrick, a Gibson assembly of K1319008 (IPTG-inducible expression of TEV protease) and the synthezised composite HSL-promotor J23101.B0032.C0079.B0015.J64010.B0034 activated by the respective autoinducers (HomoSerineLactones) was perfomed. Prior to this, we used two PCRs to linearize pSB1C3-K1319008, serving as backbone for Gibson assembly, and cutting out J23101.B0032.C0079.B0015.J64010.B0034 as well as adding adequate overlapping sequences. | * Our BioBrick K1319021 enables expression of the TEV protease inducible by the autoinducers of ''Pseumomonas aeruginosa''. In order to construct this BioBrick, a Gibson assembly of K1319008 (IPTG-inducible expression of TEV protease) and the synthezised composite HSL-promotor J23101.B0032.C0079.B0015.J64010.B0034 activated by the respective autoinducers (HomoSerineLactones) was perfomed. Prior to this, we used two PCRs to linearize pSB1C3-K1319008, serving as backbone for Gibson assembly, and cutting out J23101.B0032.C0079.B0015.J64010.B0034 as well as adding adequate overlapping sequences. | ||

| Line 167: | Line 167: | ||

| Initial denaturation || 05:00 || 98 || 05:00 || 98 || | | Initial denaturation || 05:00 || 98 || 05:00 || 98 || | ||

|- | |- | ||

| - | | Denaturation || 00:30 || 98 || 00:30 || 98 || rowspan="3" | '''30 cycles''' | + | | '''Denaturation''' || '''00:30''' || '''98''' || '''00:30''' || '''98''' || rowspan="3" | '''30 cycles''' |

|- | |- | ||

| - | | Annealing || 00:30 || 55 || 00:30 || 51 | + | | '''Annealing''' || '''00:30''' || '''55''' || '''00:30''' || '''51''' |

|- | |- | ||

| - | | Elongation || 01:35 || 72 || 00:37 || 72 | + | | '''Elongation''' || '''01:35''' || '''72''' || '''00:37''' || '''72''' |

|- | |- | ||

| Final elongation || 05:00 || 72 || 05:00 || 72 || | | Final elongation || 05:00 || 72 || 05:00 || 72 || | ||

| Line 209: | Line 209: | ||

* Production of sensor-chips was done accordingly to the [https://2014.igem.org/Team:Aachen/Notebook/Protocols/detection sensor-chip manufacturing protocol]: | * Production of sensor-chips was done accordingly to the [https://2014.igem.org/Team:Aachen/Notebook/Protocols/detection sensor-chip manufacturing protocol]: | ||

** At 13:30 we prepared sensor chips from pre-cultures of B0015, K1319017 and K131026. | ** At 13:30 we prepared sensor chips from pre-cultures of B0015, K1319017 and K131026. | ||

| - | ** Subsequently to 1 h icubation at | + | ** Subsequently to 1 h icubation at 37°C B0015, K1319017 and K131026 were induced with 0.2 µL homoserinlacton stock solution (500 µg/ml). The induced sensor-chips were read out every 30 minutes for 240 minutes in total. Readout was conducted at 450 nm and 480 nm wavelength. An additional readout was conducted after 12 hours. |

* At 17:00 we prepared 4 liquid cultures from the K1319010_pSB3K3 master plate (clone#1) in 5 mL LB-medium, each. The liquid cultures were prepared in order to create cryo stocks from K1319010-pSB3K3. Kanamycin was added to the liquid cultures as antibiotic at an concentration of 1 µL/mL. | * At 17:00 we prepared 4 liquid cultures from the K1319010_pSB3K3 master plate (clone#1) in 5 mL LB-medium, each. The liquid cultures were prepared in order to create cryo stocks from K1319010-pSB3K3. Kanamycin was added to the liquid cultures as antibiotic at an concentration of 1 µL/mL. | ||

| - | * At 18:00 we prepared a master plate (LB+C) and corresonding liquid cultures from 6 clones of ''E.coli'' NEB10B k1319021-psB1C3. Liquid cultures and master plate were incubated at | + | * At 18:00 we prepared a master plate (LB+C) and corresonding liquid cultures from 6 clones of ''E.coli'' NEB10B k1319021-psB1C3. Liquid cultures and master plate were incubated at 37°C. |

| - | * At 23:30 we prepared liquid cultures from K1319015-pSB3K3 clones #7, #8 and #9 in 5 mL LB-medium. Kanamycin was used as antibiotic and the cultures were incubated at | + | * At 23:30 we prepared liquid cultures from K1319015-pSB3K3 clones #7, #8 and #9 in 5 mL LB-medium. Kanamycin was used as antibiotic and the cultures were incubated at 37°C. Purpose of the cultures was cryo stock preparation and plasmid prep. |

==5th == | ==5th == | ||

| Line 226: | Line 226: | ||

* Production of sensor-chips was done accordingly to the [https://2014.igem.org/Team:Aachen/Notebook/Protocols/detection sensor-chip manufacturing protocol]: | * Production of sensor-chips was done accordingly to the [https://2014.igem.org/Team:Aachen/Notebook/Protocols/detection sensor-chip manufacturing protocol]: | ||

** At 13:00 we prepared sensor chips from shake flask pre-cultures of BL21 pSB1C3-K1319008+pSB3K3-K1319014, BL21 pSB1C3-K1319008+pSB3K3-K1319013 and NEB pSB1C3-B0015. | ** At 13:00 we prepared sensor chips from shake flask pre-cultures of BL21 pSB1C3-K1319008+pSB3K3-K1319014, BL21 pSB1C3-K1319008+pSB3K3-K1319013 and NEB pSB1C3-B0015. | ||

| - | **Subsequently to 1 h incubation at | + | **Subsequently to 1 h incubation at 37°C, BL21 pSB1C3-K131900+pSB3K3-K1319014, BL21 pSB1C3-K1319008+pSB3K3-K1319013 and NEB pSB1C3-B0015 were induced with 0.2 µL IPTG. The induced sensor-chips were read out every 30 minutes for 360 minutes in total. K1319013 was induced earlier and thus measurements were taken for 450 min in total. Readout was conducted at 480 nm wavelength. An additional readout was conducted next day at 11:00. |

* At 15:30 we prepared liquid cultures for the characterization of ITPG inducible expression: | * At 15:30 we prepared liquid cultures for the characterization of ITPG inducible expression: | ||

| Line 298: | Line 298: | ||

* made a master plate at 15:30 containing two clones of K1319015 plate from yesterday. | * made a master plate at 15:30 containing two clones of K1319015 plate from yesterday. | ||

| - | * At 22:00 we inocculated two 500 ml flasks containing 50 ml LB-medium with 1 ml pre-culture of K1319017, which had been prepared from a master-plate earlier this day. Chloramphinicol was used as antibiotic. The flasks were incubated at | + | * At 22:00 we inocculated two 500 ml flasks containing 50 ml LB-medium with 1 ml pre-culture of K1319017, which had been prepared from a master-plate earlier this day. Chloramphinicol was used as antibiotic. The flasks were incubated at 37°C. One culture (50 ml) was induced with 25 µg homoserinlacton after an OD of 0.6 was reached and the induced culture as well as the control were used for fluorescence characterization. Fluorescene and OD were monitored once per hour. The OD of the induced culture stagnated at ~0.7 while the non induced culture grew further. |

== 7th == | == 7th == | ||

| Line 355: | Line 355: | ||

* SOC medium was added to the transformation before the heat shock had occurred by mistake. | * SOC medium was added to the transformation before the heat shock had occurred by mistake. | ||

* At 02:00 the precultures for the characterization experiment were transferred to 250 ml shake flasks (3 ml culture + 10 ml LB+antibiotics). | * At 02:00 the precultures for the characterization experiment were transferred to 250 ml shake flasks (3 ml culture + 10 ml LB+antibiotics). | ||

| - | * new transformation of the ligation product was conducted into BL21 and | + | * new transformation of the ligation product was conducted into BL21 and DH5α |

* At 23:00 a 500 ml flask containing 50 ml LB-medium was inocculated from a K131026 BL21 cryo stock for sensor-chip manufacturing the following day. | * At 23:00 a 500 ml flask containing 50 ml LB-medium was inocculated from a K131026 BL21 cryo stock for sensor-chip manufacturing the following day. | ||

| Line 403: | Line 403: | ||

==13th== | ==13th== | ||

| - | * overnight culture of K131026 in BL21 for | + | * overnight culture of K131026 in BL21 for chips |

==14th== | ==14th== | ||

Latest revision as of 22:09, 17 October 2014

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"

"