Achievements

We are able to detect IPTG, 3-oxo-C12 HSL and Pseudomonas aeruginosa. To prove that the sensor constructs produce the flourescence signal and not the medium or E. coli in its own we have [http://parts.igem.org/Part:BBa_B0015 B0015] in NEB as a negativ control for IPTG, HSL and Pseudomonas aeruginosa induction.

Testing our Sensor Chips in a Plate Reader

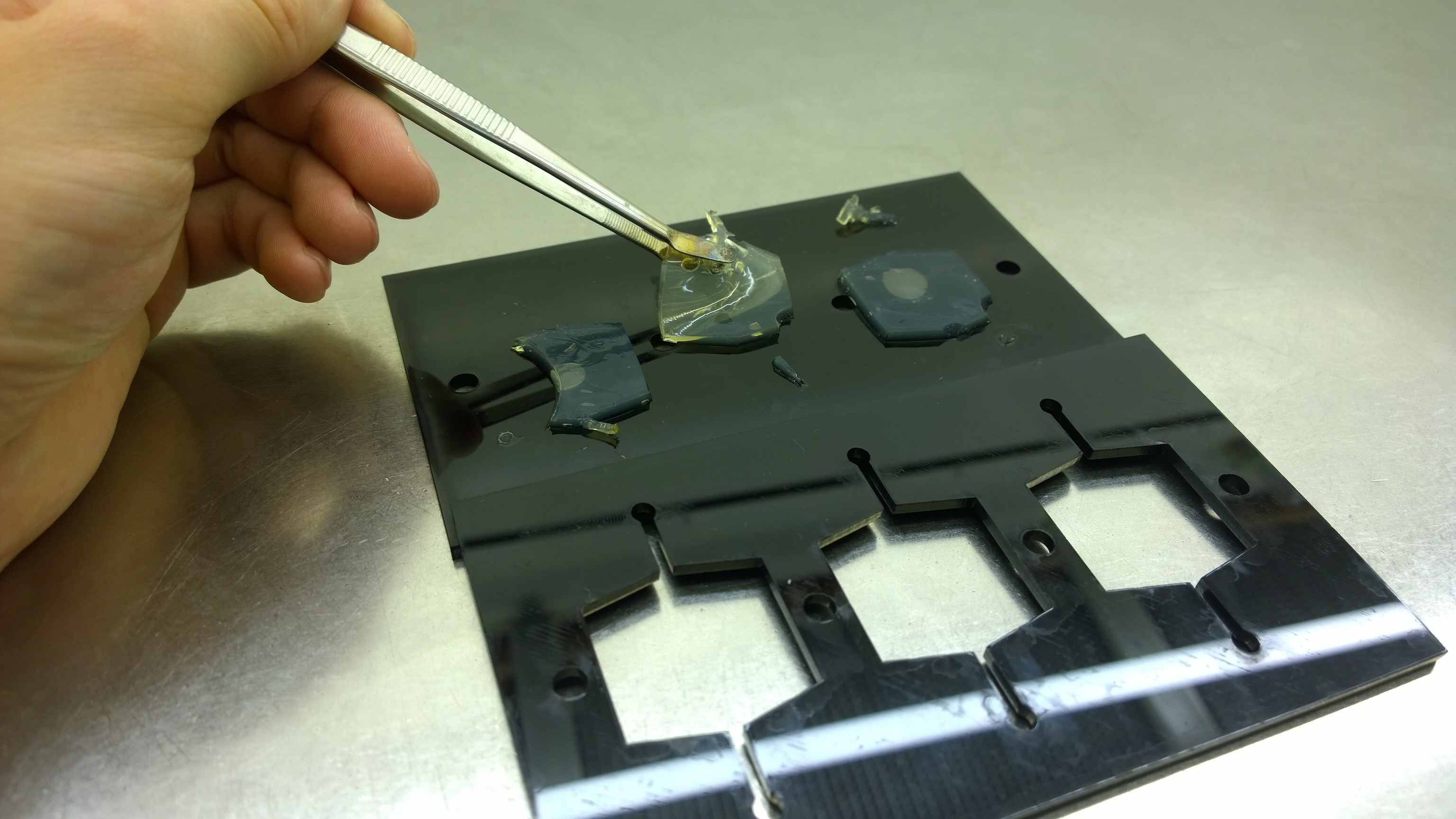

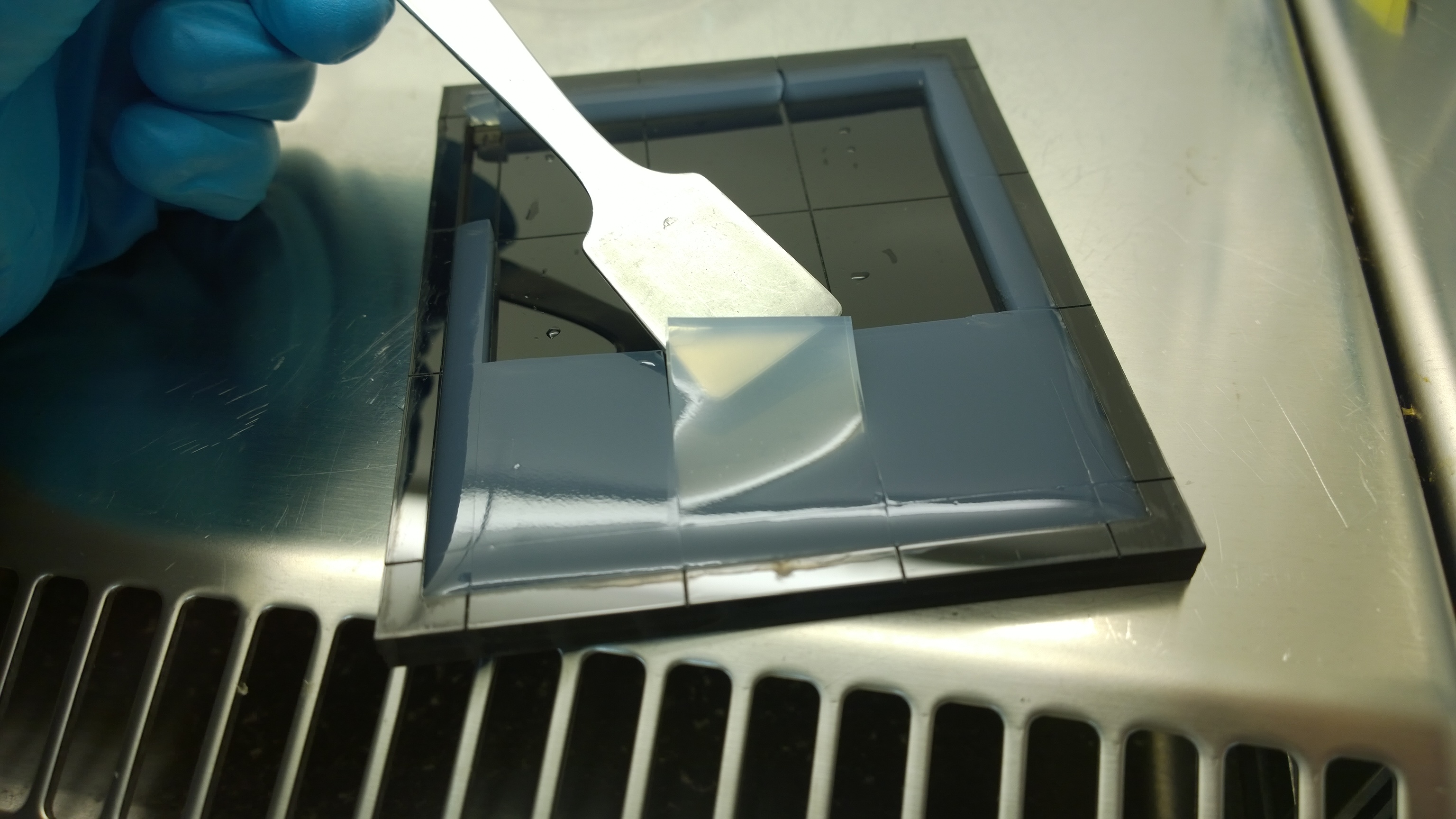

To establish a prove of principle we used our construct [http://parts.igem.org/Part:BBa_K1319042 K1319042] an IPTG inducible iLOV. They were introduced into our sensor chips and then fluorescence was measured every 15 minutes after an induction with 2 µl 100 mM IPTG (gif on the left).

There is a clear difference in fluorescence between the not induced chip (top) and the induced chip (bottom). It is distinctively visible that the middle of the bottom chip start to exhibit fluorescence and then the fluorescence increases over time and spreads outward. The top chip also shows a slight increase in measured fluorescence but it is nowhere near the level of the induced chip and is primarily attributable to a leaky promoter and the background fluorescence.

This demonstrates a general proof of principle of the sensor chip design. Therefore the next was testing the detection of 3-oxo-C12 HSL.

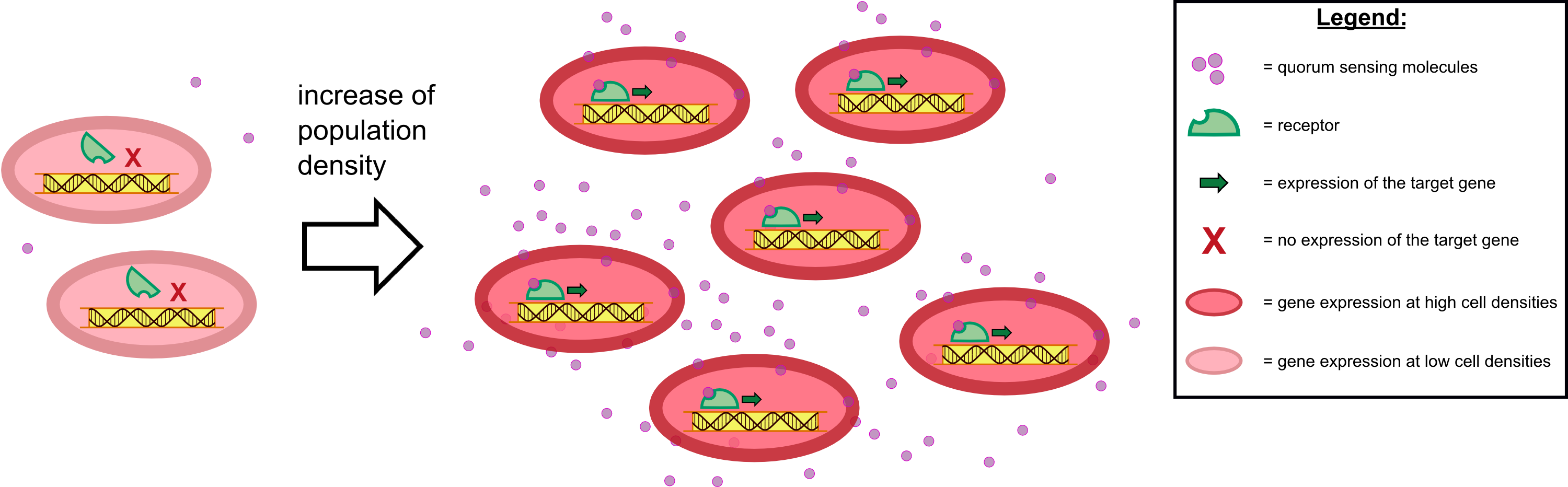

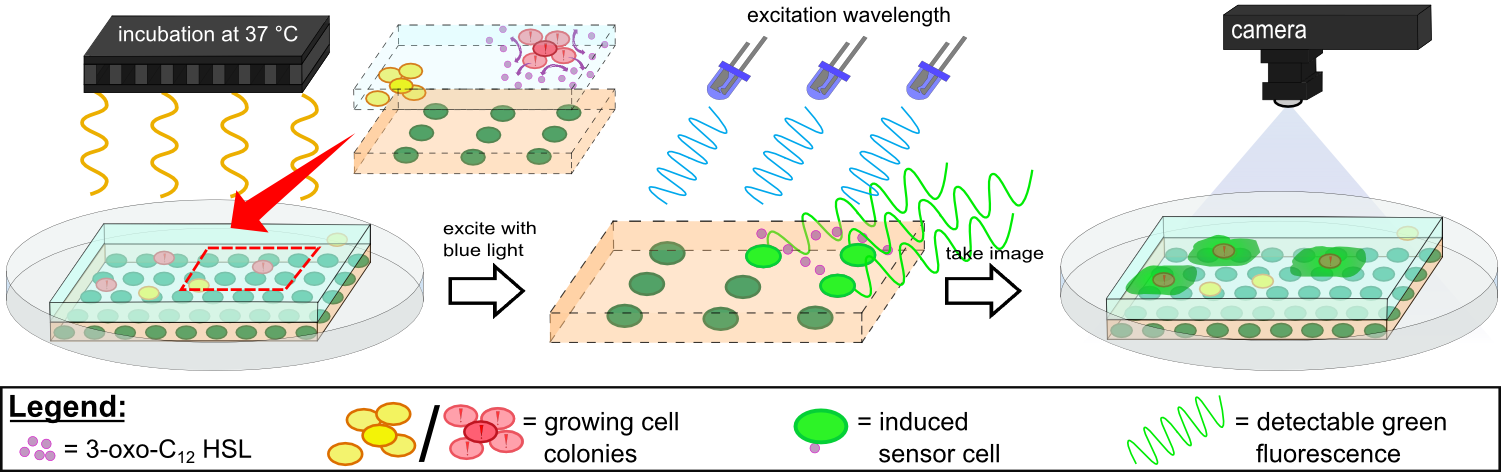

Detecting 3-oxo-C12 HSL with Sensor Chips

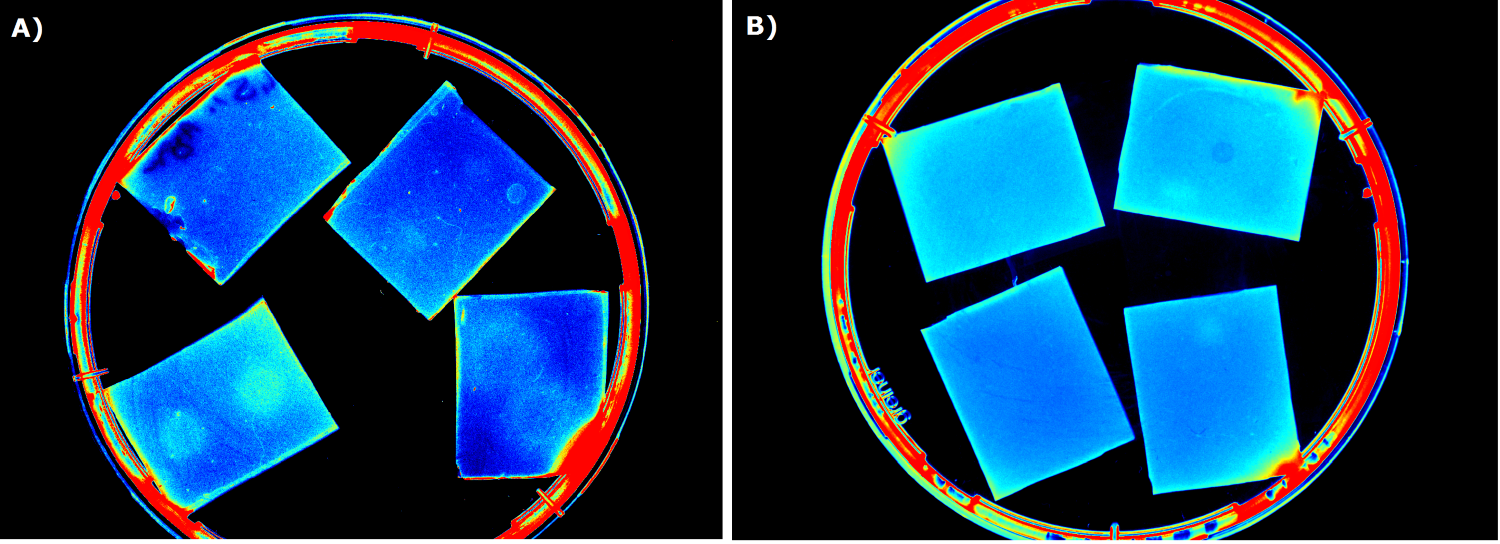

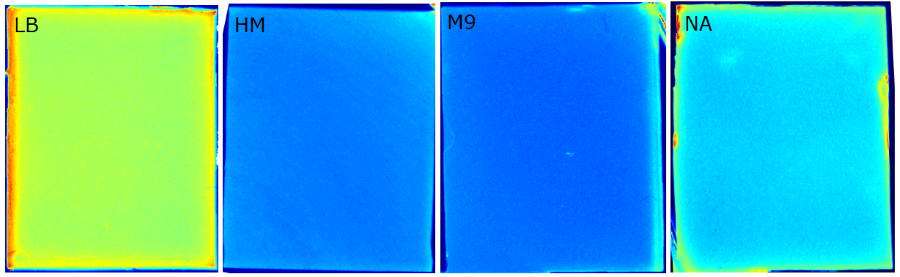

As a next step, we used [http://parts.igem.org/Part:BBa_K131026 K131026] from the 2008 iGEM Team Calgary in our sensor chips to detect 3-oxo-C12 HSL which is produced by Pseudomonas aeruginosa during quorum sensing. First, we tested them by direct induction with purified 3-oxo-C12 HSL (0.2 µL, 500 µg/mL). A fluorescence measurement was taken every 15 minutes with an excitation wavelength of 496 nm and an emission wavelength of 516 nm (for GFP).

The measured fluorescence again showed a distinct signal on the induced chip (bottom) compared to the uninduced chip (top). The fluorescence clearly starts in the middle of the chip (point of induction) and then extends outwards, still showing an ever increasing signal of fluorescence. The base level of fluorescence is attributed to leakiness of the promoter and general background fluorescence of growing E. coli cells. In the induced chip (bottom), the background fluorescence is a lot lower than in the uninduced chip (top) because the signal masks the noise. The difference between the induced and uninduced chips indicates a clear response to the HSL and a proof for the ability of our sensor chip design to detect the HSL produced by Pseudomonas aeruginosa.

Detecting IPTG with Sensor Chips

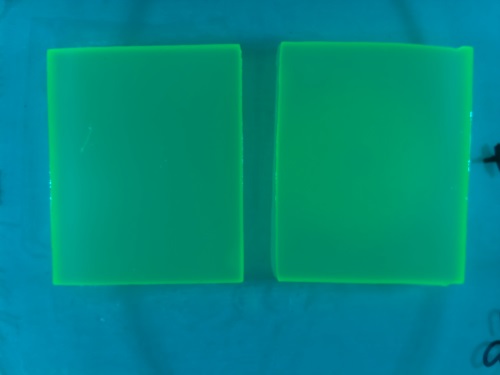

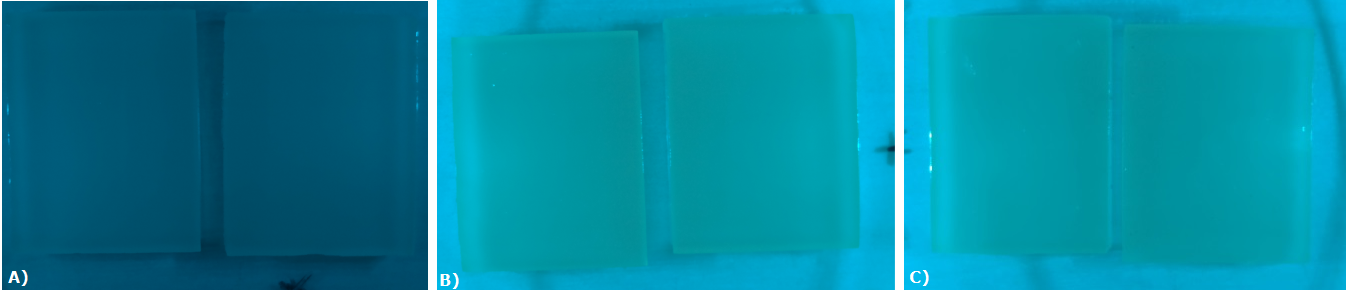

This video shows the construct [http://parts.igem.org/Part:BBa_I746909 I746909] from the 2007 iGEM Team Cambridge. This BioBrick is a producer of superfolder GFP under the control of a T7 promoter. It was introduced into BL21(DE3) cells making the expression IPTG inducible through the T7 RNA Polymerase encoded in the genome of BL21(DE3) under the control of a lacI promoter.

The left chip does not show visible fluorescence and the right chip exhibits a strong fluorescence signal showing clearly the ability of the sensor chip technology to detect IPTG. On top of that, the fluorescence response is strong enough to be detected and analyzed by the measurement device WatsOn.

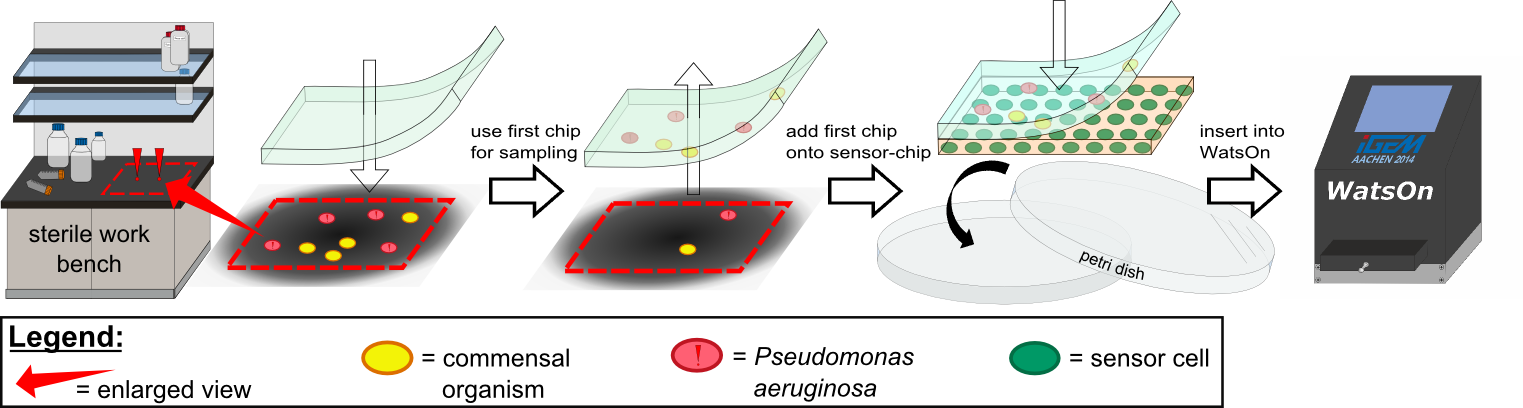

Detecting the 3-oxo-C12 HSL with K131026 in our Sensor Chips with WatsOn

The next step towards the final goal to detect Pseudomonas aeruginosa was to replicate the detection of 3-oxo-C12 HSL, which was established in the plate reader, in our own WatsOn device. Therefore, we again used K131026 as our construct in E. coli BL21(DE3) cells and induced with 0.2 µL 3-oxo-C12 HSL with a concentration of 500 µg/mL. The right chip was induced and - as a negative control - the left chip was not induced. Pictures were taken every 4 minutes.

The result was a clear replication of the success of the plate reader experiment. The induced chip shows a clear fluorescence response eminating from the center where the induction with HSL took place. This demonstrates the ability of not only our sensor chips but also our measurement device WatsOn to successfully detect 3-oxo-C12 HSL.

Detecting Pseudomonas aeruginosa with K131026 in our Sensor Chip with WatsOn

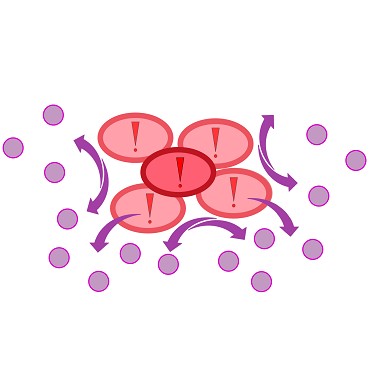

After establishing the successful detection of 3-oxo-C12 with our sensor chips the next step was the detection of Pseudomonas aeruginosa with our measurement device WatsOn. Therefore sensor chips with K131026 were again prepared and the right chip was induced with 0.2 µl of a Pseudomonas aeruginosa culture while the left chip was not induced.

The results clearly demonstrate our ability to detect Pseudomonas aeruginosa with our measurement device WatsOn. On the induced chip a definite fluorescence response is visible in response to Pseudomonas aeruginosa. The fluorescence eminates outward from the induction point and shows a significant difference to the non induced chip. Therefore detection of Pseudomonas aeruginosa is possible with our sensor chip technology in our measurement device WatsOn!

|

"

"