|

Protocol

1:miniprep

- ・We took plasmid out of Escherichia coli which have a gene of IL-10 α and IL-10 β and STAT3 in miniprep to use it by a following experiment (the Escherichia coli which I really used in an experiment of 2013).

DNA of HlyA and the GFP are IGEM 2014 kit plate1 21G and IGEM 2014 kit plate 13L, so we didn't miniplep

- 1) We cultured bacterial strain with the LB medium which I added ampicillin to so that density becomes 100ug/ml overnight.(We made a nutrient medium of around 5 ml in 50 ml falcons)(Against 5 ml of nutrient mediums, Amp used 5ul)

- 2) Aliquot 1ml culture into a 1.5 ml microcentrifuge tube,and Made it spin at 10000rpm (4℃) for 1 min to harvest the bacteria.

- 3) Removed supernatant and performed 2)operation again, Removed supernatant .

- 4) Resuspended bacterial pellet by complete vortexing in 100ul SolutionⅠ{D-glucose:9g(50mM),1M Tris-HCl(pH 8.0):25ml(25mM),0.5M EDTA:20ml(10mM),H2O:955ml /1L}.

- 5) Inverted bacterial pellet by complete fall mixtureing in 200ul SolutionⅡ{NaOH:8g,SDS:10g[1%(w/v)],H2O:960ml /1L},and confirmed that it became transparent.

- 6) Cooled for three minutes in ice.

- 7) Inverted bacterial pellet by complete fall mixtureing in 150ul SolutionⅢ{CH3COOH:294.5g(3M),CH3COOH:120ml(2M),H2O:diluting in measuring cylinder to 1L total},and confirmed that it became Cloudiness.

- 8) Cooled for 3 minutes in ice.

- 9) Harvested the DNA by spinning at 10000rpm (4℃) for 10 min.

- 10) Gathered only supernatant and moved it in a new microcentrifuge tube.

- 11) Added 0.8ul Rnase(10mg/ml) and incubate the solution(37℃,1min)

- 12) Added 200ul phenol:chloroform(1:1) and inverted

- 13) Harvested by spinning at 10000rpm (4℃) for 5 min.

- 14) Removed only supernatant and moved it in a new microcentrifuge tube, after that tapped in 200ul chloroform.

- 15) Harvested by spinning at 10000rpm (4℃) for 1 min.

- 16) Moved its supernatant to a new microcentrifuge tube and add 15ul 3M CH3COONa.(Don't gather underlayer)(The ratio of the 3M sodium acetate and supernatant is made to be 10:1)

- 17) Added 400ul 100%CH3CH2OH and made it stirred well.

- 18) Harvested by spinning at 10000rpm (4℃) for 20 min.

- 19) Removed only supernatant and added 400ul 70%CH3CH2OH(pour a liquid from the other side for white thing not to drain a white.[white thing is plasmid])

- 20) Harvested by spinning at 10000rpm (4℃) for 20 min.

- 21) Removed only supernatant and opened the cover of the tube for 10min to dry CH3CH2OH.

- 22) Added 50ul TE to dissolve DNA

- 23) We stored low temperature

2:PCR

- ・We performed PCR to confirm whether DNA which we need.

- 1)We diluted the primer.(D2W:primer=4:1)

- 2)Made PCR preparation liquid {buffer×10:2.5ul,dNTP:2ul,PrimerF:1ul,PrimerR:1ul,Taq Polumerase:0.1ul,D2W:17.39ul /1 microcentrifuge tube(0.2ml)}

- 3)Added sample(there are Plasmid made with miniprep)to the microcentrifuge tube and do PCR(The PCR conditions are as follows).

- Figure①:PCR condition of STAT3 ,IL-10a and IL-10b

- [②→③→④]:repeated 35~40 cycles

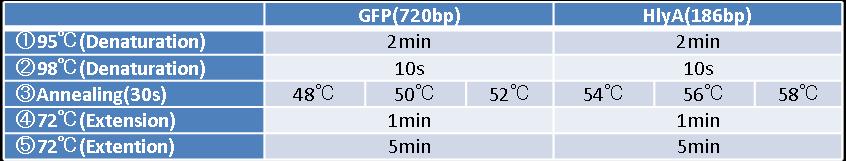

- Figure②:PCR condition of GFP and HlyA

- [②→③→④]:repeated 40 cycles

- 4)We did Electrophoresis to confirm Objective band.

3:Restriction enzyme processing

- ・We did restriction enzyme processing to plasmid to incorporate inserts in a plasmid vector.

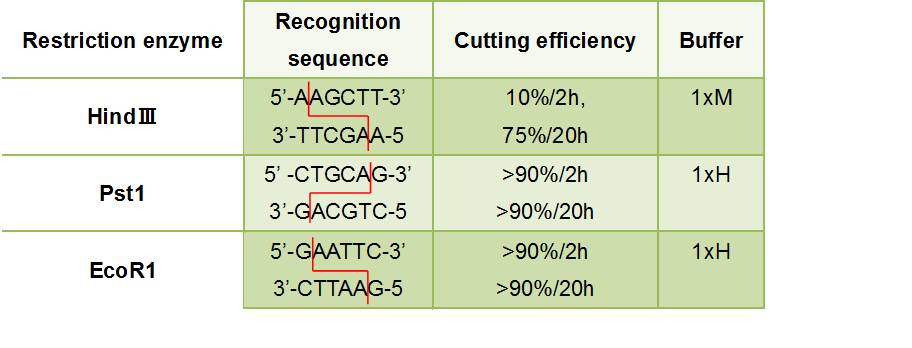

- Figure③:Used Restriction enzyme

- HlyA・・・We removed the stop codon

- F chain ・・・This has EcoR1 recognition sequence.We added CG and A to this to prevent flame out.

- ・5'-CGGAATTCATTAGCCTATGGAAGTCAGGG-3'

- ((Tm before adding a restriction enzyme site =60℃

- ((GC before adding a restriction enzyme site =50.0%

- R chain ・・・This has HindⅢ recognition sequence.We added CCC to this.

- ・5'-CCCAAGCTTTGCTGATGTGGTCAGGGTTA-3'

- ((Tm before adding a restriction enzyme site =60℃

- ((GC before adding a restriction enzyme site =50.0%

- GFP

- F chain ・・・This has HindⅢ recognition sequence.We added CCC and A to this to prevent flame out.

- ・5'-CCCAAGCTTAATGCGTAAAGGAGAAGAACT-3'

- ((Tm before adding a restriction enzyme site =56℃

- ((GC before adding a restriction enzyme site =40.0%

- R chain ・・・This has Pst1 recognition sequence.We added AA to this.

- ・5'-AACTGCAGTTATTATTTGTATAGTTCATCC-3'

- ((Tm before adding a restriction enzyme site =54℃

- ((GC before adding a restriction enzyme site =22.7%

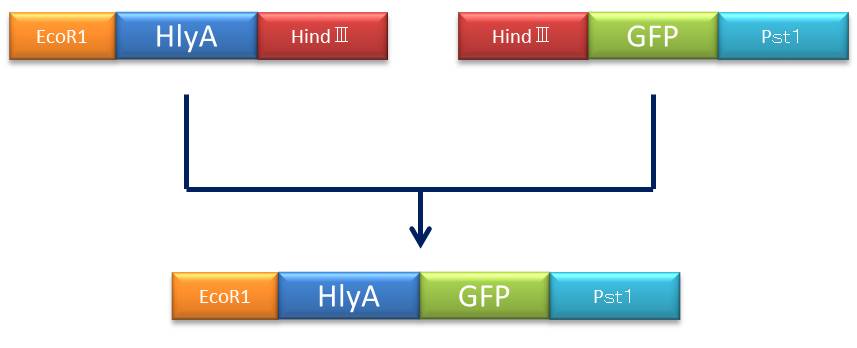

- Figure④:Rough plan

- 1)We set a heat block(37℃).

- 2)prepare one microtube.

- 3)added 1ul restriction enzyme buffer(×10) to microtube

- 4)added 1ul DNA sample liquid to the microtube

- 5)added 1ul each restriction enzyme to the microtube

- 6)added D2W until it became 10ul

- 7)set microtube to a heat block (37℃)

- 8)left the microtue more than one hour to push forward a reaction

4:Ligation

- ・We did restriction enzyme processing to plasmid to incorporate inserts in a plasmid vector.

5:Transformation

- ・We did restriction enzyme processing to plasmid to incorporate GFP+HlyA in a plasmid vector.And we incorporated GFP+HlyA in plasmid by ligation processing

- 1)We put 1μℓeach plasmid into 3 microtubes.(used plasmid are pCold vectorⅠ(4407bp),pCold vectorⅡ(4392bp) and pSBIC3)

- 2)Put 1ul PstⅠand 1ul EcoRⅠinto each microtube.

- 3)Put 1ul ×10 H buffer into each microtube.

- 4)Up to 10ul with D2W.

- 5)Did heat block(37℃) about 2hour.

- 6)Prepared 3 new microtubes.and added 10ul GFP+HlyA into them.

- 7)added D2W until it became 10ul

|